In mid-March, Orient Craft’s Ranchi unit was facing difficulties to get masks for its workers, but a few days later, the same unit produced thousands of masks with colourful fabrics (which were actually stocked for garments) and distributed those masks to the nearby villages also. Now the company is producing Personal Protective Equipment (PPE) in Ranchi as well as in its Bhiwandi unit.

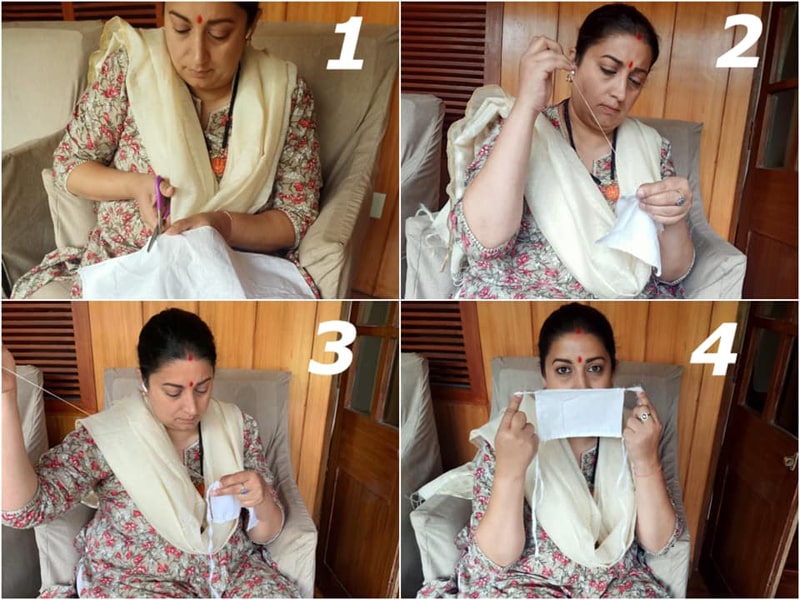

In the last two weeks, thousands of women have initiated to be a part of mask manufacturing with their limited resources. Indian apparel manufacturing industry is also not behind, as they are not only making masks but also complete PPE sets including body coveralls, gloves, shoe covers, etc. And this is proving to be a commercially viable product category and a saviour in this time of crisis. Even those without required machinery and knowhow are into simple mask making.

Now in the month of April, leading apparel exporters across India like Shahi Exports, Faridabad; Eastman Exports Global Clothing, Tirupur; Radnik Exports, Noida; Pratibha Syntex, Indore; Matrix Clothing, Gurugram; Shingora Textiles, Ludhiana; domestic giants like Raymond, Aditya Birla Group, Arvind Ltd.; and home textile giant, Trident Group, Ludhiana among many other companies are actively producing PPE. Most of them see this as a long-term product category going ahead, as these products will be more in demand across the globe in future.

Shahi Exports is making 10,000 pieces of PPE per day and will continue to increase the capacity for the same. Textile Secretary Ravi Capoor has appreciated this initiative by the company.

Pratibha Syntex, which is currently making 6,000 pieces of body coveralls per day, has the target to reach 15,000 per day. The company started this venture with 50 workers and now almost 700 workers are involved in the same. Similarly, Shingora Textiles is making 1,500 pieces per day, and in future, it targets to make 5,000 pieces per day.

In the beginning, the production for this entirely new product domain was not easy at all, as there were several challenges on the way, like availability of raw material and implementation of high level of technology. The Pratibha Syntex team had to give on-job training to workers and even practised at night too. Shingora Textiles had started this exercise two years back for armed forces, but things could not move due to certain reasons. Even now they failed twice in mastering this product category before tasting success.

“We already have state-of-the-art unit and high adaptability of technology, so despite the challenges, we have done it,” said HS Jha, VP, HR, Pratibha Syntex. The company also underwent inspection by the team of DRDO who checked all the working stations and gave certain directives.

Fit is always an issue for Indian apparel manufacturers and it is applicable to even body coveralls. Companies are, therefore, following standard sizes and are making medium, large and extra-large sizes with reasonable use of lycra. It is pertinent to mention here that SITRA and DRDO are the official agencies regarding approval for PPE. It is also advised by the authorities to keep the manufacturing process in a packed room, pass all raw materials through a tunnel of disinfectants, and disinfect workers after every few hours.

Ludhiana, Surat, Pune, Bengaluru, Coimbatore, Agra and Bhiwandi are some of the hubs where the raw material is being sourced by the majority of PPE manufacturers. Every PPE manufacturer is of the strong view that there is less availability of raw material and that they are very highly priced. “Be it tape, thread or any trims used for these products, suppliers are ready to supply only on cash payment. Despite that, they are charging high, and even we don’t have any option or solution in this regard,” said Anuj Jain, CEO, Shingora Textiles Ltd. (OEM division), although the Ministry of Textiles has claimed that textiles officials are continuously working towards increasing capacity of the material.

Not only PPE manufacturers, but even the fabric manufacturers of this product category are facing difficulties to find the material. Guru Kirpa Tex Fab, Ludhiana, is one of the approved suppliers for raw material and the company noticed a surge of demand all of a sudden by around 10 times. Having a production facility in Himachal Pradesh, currently it has a capacity of 10 tonnes per day. Ashish Gupta, Director of the company, shared, “We are also facing this challenge of increased price, especially as far as some of the imported material regarding quoting is concerned. On the other side, the melt-blown medicated paper is not available now.” Despite that, there has been 10 times increase in demand; Ashish is not planning to increase capacity as he feels that it is not possible. “It will take more than 6 months from finalisation of orders to installing of the new imported machines,” said Ashish. The company also produces anti-dust 3-ply masks.

Despite the issue of raw material, the product produced in India is almost 20 to 30 per cent cost-effective as compared to the Chinese ones. Though nearly all the companies, right from the raw material suppliers to end-product manufacturers, have appreciated the Government’s support, be it for logistics movement or guidance. Anuj informed that everyone in the Government is now fully supportive.

Meenu Creations, Noida, which is also in the process to start the production of the same, however has a different view. The company found that the approval conditions for the product are very stringent, and getting approval from local administration is also very difficult. Anil Peshawari, MD of the company, told, “We have shared all the details of workers and whatever else they asked a few days ago. Despite our best efforts, we still have not got any approval to start work. Everyone in local administration is trying to save his skin.” The companies, which are having hostel facilities for workers and are better equipped to adhere to safety measures, have got permission for PPE production during the lockdown period.

Client base

HLL Lifecare, the Government’s nodal agency for procuring PPE required 7,25,000 body covers, 1.5 million N-95 masks and one million 3-ply masks for which many companies have been supplying products to it. Many companies have even directly contacted hospitals and got orders. Most of the companies are supplying to Government agencies and hospitals on priority basis.

Apart from the core industry, allied stakeholders have also entered this product line. Khadi and Village Industries Commission (KVIC) has developed a double-layered khadi mask and has procured orders for supplying it in large quantities. It bagged an order to supply 7.5 lakh pieces of khadi masks to the Jammu & Kashmir Government alone. The cotton reusable mask will be of 7 inches (length) by 9 inches (breadth) with three pleats, and four strips at the corner for tying. As per V K Saxena, Chairman, KVIC, “KVIC is specifically using double-twisted khadi fabric for the manufacturing of these masks, as it helps retain 70 per cent of the moisture content inside, while providing easy passage for the air to pass through, hence proving to be the best easily available, pocket-friendly alternative face masks.”

These masks are more special because they are made of hand-spun hand-woven khadi fabric, which is breathable, can easily be reused, washable and biodegradable. In one-metre khadi fabric, 10 double-layered masks will be made. World University of Design (WUD) has joined hands with IIT and AIIMS to design and size a standard PPE gown. As per Sanjay Gupta, Vice-Chancellor of WUD, “It is easy and quick to doff without getting in touch with an infected surface.”

Experts believe that there will be an issue of oversupply of PPE but after at least 6 to 8 months. Indian apparel manufacturers strongly believe that as coming months are critical, PPE emerged a big support for them. In future, they will explore export opportunities in the same and allied products.

Even though there are factories making PPE and also providing good hostel facilities, most of them are still facing labour shortage, and so, are unable to grab orders.

Heat-sealing machine is critical for the production of hazmat suits and is currently not easily available. Few of the apparel manufacturers already have these machines as they were producing outerwear. Other industry sources confirmed that they have been told to wait for one month or even more for the delivery of these machines.