In a turbulent world where rising labour costs, scarce skilled workers and economic volatility threaten margins, innovation isn’t optional, it’s a matter of survival. At CISMA 2025, this urgency was on full display as leading providers of cutting, sewing, fusing and finishing solutions unveiled technologies designed to boost productivity, improve quality and reduce operational risks.

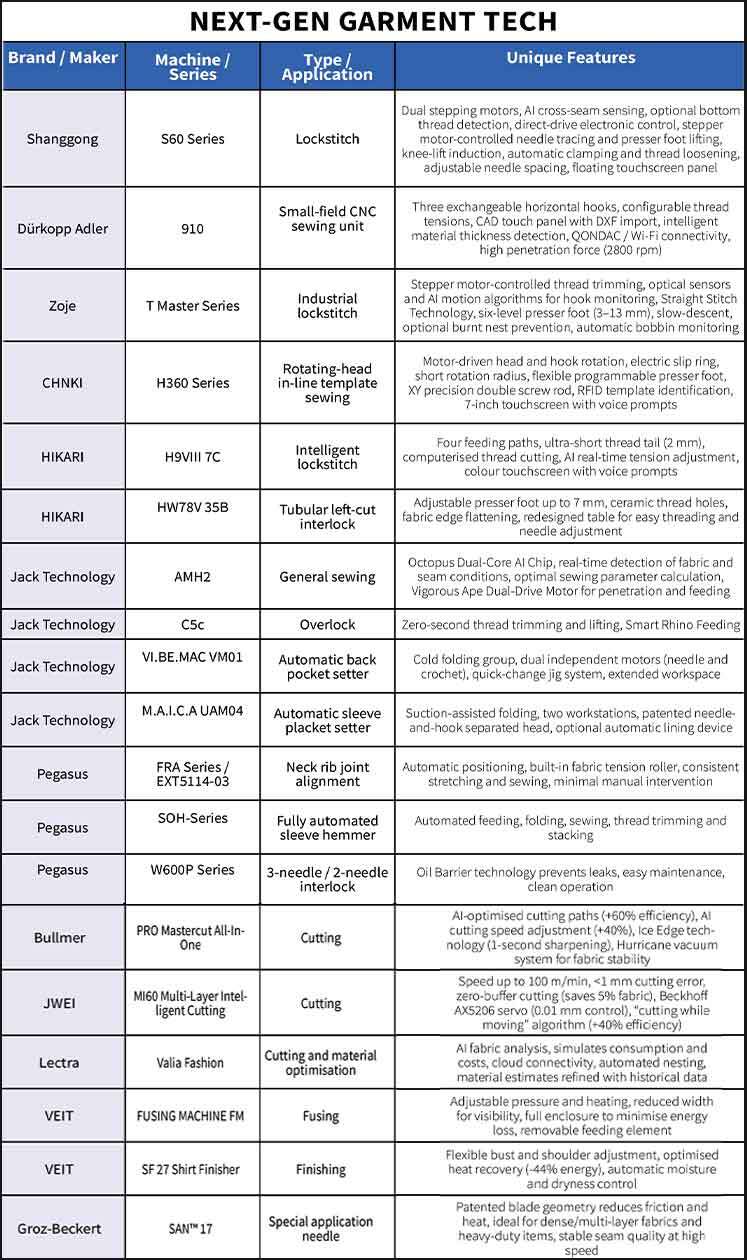

Shanggong’s AI-enabled S60 lockstitch series, Dürkopp Adler’s CNC-controlled 911R pattern stitcher, Zoje’s sensor-equipped T Master and Pegasus’s automated hemming and pocket-setting units stood out for their precision, consistency and reduced reliance on manual intervention.

| CISMA 2025 made it clear that AI integration, intelligent oil and lubrication management and fully automated auxiliary systems such as pocket setters and sleeve placket units are increasingly becoming a standard feature in modern garment manufacturing. |

Cutting-edge systems from Bullmer, JWEI and Lectra demonstrated how precision engineering optimises material usage, while VEIT’s energy-efficient fusing and finishing solutions reinforced the move towards sustainable production.

The event also made it clear that AI integration, intelligent oil and lubrication management and fully automated auxiliary systems such as pocket setters and sleeve placket units are increasingly becoming a standard feature in modern garment manufacturing.

Even the smallest components were reimagined. Groz-Beckert’s SAN™ 17 special application needle and the upgraded INH 2.0 digital needle handling platform proved that innovation at every level, from thread handling to fabric feed, can enhance efficiency across production lines.

Whether it’s small-batch production, multi-fabric handling or ultra-high-speed operations, the exhibition showcased how technology can transform challenges into opportunities, helping manufacturers deliver quality at scale while reducing waste, downtime and operational risk.

Cutting-Edge Sewing Solutions

Innovations demonstrated at CISMA 2025 showed how precision, consistency and reduced manual intervention are becoming non-negotiable in modern garment production.

For instance, Chinese sewing technology leader ShangGong Group (SGG), displayed Shanggong S60 series, which comprises intelligent double stepping motor-controlled lockstitch machines. These lockstitch machines operate at speed up to 5000 rpm, produce low noise of 77 dB at 4000 rpm and minimal vibration of 55 μm. Developed on the Qixing dual step control system platform, they integrate direct-drive electronic control, stepper motor-controlled needle tracing, presser foot lifting, thread cutting, knee-lift induction, automatic clamping and automatic thread loosening. The chassis features a redesigned look with a floating touchscreen control panel. Needle spacing is adjustable through the operation panel, allowing variable spacing, dense sewing and pattern stitching. Stepper motors precisely control thread trimming and presser foot lifting (10 mm lift, 60 dB noise), while double-blade wire cutting reduces noise and eliminates large cam crank components.

Building on this emphasis on precision and automation, Dürkopp Adler, a subsidiary and part of the SGG, showcased its 911R-210-10 series, a CNC-controlled rotating-head pattern stitcher for medium-to-heavy applications. Available in sewing areas from 300×200 mm (911R-210- 3020-10) up to 1000×550 mm (911R- 210-10055-10), this machine ensures perfect seam positioning with infinite clockwise and counter-clockwise rotation. Mechanical synchronisation of hook, needle and sewing foot guarantees uniform stitching. Integrated bobbin thread monitoring, short thread trimming (≤5 mm), programmable thread tension and adjustable sewing foot height allow precise operation. Optional DA SPOT software optimises seam placement by detecting perforation deviations in the material and recalibrating seam positions automatically. The system is QONDAC-equipped, ready for Industry 4.0 integration.

Whereas, Dürkopp Adler 910, a CNC small-field sewing unit for medium-to-heavy applications, features three exchangeable horizontal hooks, four selectable sewing areas (150×100 mm to 300×200 mm) and three configurable thread tensions (mechanical, electronic or combined). Its fully integrated CAD touch panel allows direct on-machine programming, including DXF file import for faster set-up. Programmable foot height and stroke, along with intelligent material thickness detection, ensure consistent stitching across fabrics. The 910 connects to Industry 4.0 systems via QONDAC plug-and-play or Wi-Fi and supports high penetration force up to 2,800 rpm for challenging materials.

“This line features a new human-machine interface with our own CAD technology built into the screen. You can easily use a mouse to make adjustments directly on the machine—no need to go to a separate computer or use a USB stick. This makes programming much easier, whether on the Durkopp Adler CAD system or directly on the machine,” mentioned Michael Kilian, COO, Dürkopp Adler.

He also noted that while cost remains critical in machinery decisions, features supporting sustainability are increasingly in demand. “Some clients only care about purchase price, but many consider sustainability, power consumption and efficiency,” he added.

Another prominent sewing machines manufacturer from China, Zoje addressed common production headaches with its T Master series, consisting of high-precision industrial lockstitch machines that integrate advanced stepper motor-controlled thread trimming, optical sensors and AI motion algorithms for monitoring hook movement and remaining bobbin thread. It supports Straight Stitch Technology for consistent stitch quality and adapts to thick, thin and elastic fabrics. The six-level digitally adjustable presser foot (3–13 mm) with slow-descent technology protects fabrics while maintaining precision. Reverse sewing noise is reduced below 20 dB, one-line pattern sewing supports up to nine editable patterns and customisable pedal sensitivity improves stitching efficiency by up to 10%.

“Bird nests are always a big headache for garment factories. Our TMaster has a built-in device to prevent burnt nests, keeping the machine nearly clean, an optional but major advantage. Fabric joints—light or thick areas— can affect stitch length, so an optional sensor ensures consistent stitching. Additionally, the bobbin can be monitored: if thread isn’t enough for a piece, the machine stops automatically, eliminating the need for thread joining stations, said Sam Wang, India Market Director, Zoje T Master will be launched in India by Q2 2026.

Adding to the line-up of innovative machines, CHNKI’s H360 series offered 360 degree rotating-head in-line template sewing machines with multiple variants including H360, H360 JG with laser cutting, H360 JG-XF with laser and suction and H360 HB with chalk function.

“These machines feature individual motor-driven head and hook base rotation with electric slip ring to eliminate backward sewing and save time during empty feeding, a short 100 mm rotation radius for flexible corner sewing, a fully enclosed cylindrical head to prevent operator injuries, high-speed angle sewing with one-piece casting of body and base and high-rigidity screw drive structure to avoid thread distortion and an exquisite stitch solution for special-shaped patterns,” mentioned Zhou Yi Yi, Brand Promotion Director, Chnki.

The H360 machines also include a flexible, programmable intermediate presser foot powered by an independent motor, XY precision double screw rod with double closed-loop control, stable round knife thread trimming, dual hooks to reduce bobbin changes, upper thread breakage detection, RFID technology for template identification, rigid template frame presser, switchable U-groove installation, emergency stop button, a 7-inch touch screen panel with voice prompts and a bobbin winder for easy thread changes.

In a similar vein, Hikari demonstrated HI-85250, a template-free machine that allows direct stitching of garment edges without templates, covering a maximum operating space of 310×140 mm. Whereas, the HIKARI H9VIII 7C intelligent lock stitch machine offers four adaptable feeding paths, ultra-short thread tail of 2 mm, computerised thread cutting for smooth, quiet operation and a user-friendly colour touchscreen with voice prompts. The HIKARI HW78V 35B intelligent tubular left-cut interlock sewing machine delivers full and beautiful stitches, with presser foot height adjustable up to 7 mm, ceramic thread holes, fabric edge flattening and a redesigned sewing table for easy threading and needle adjustment.

“We focus on solving key issues at the source such as puckering and thread breakage. While other imported brands address these with adjustments to the feed dog or presser foot, those solutions only solve part of the problem. Thread breakage occurs due to excessive tension and puckering happens when the thread is pulled too fast between stitches.”

“Our design reduces thread tension— to just one-third of the original for single lock stitch and interlock sewing machines, Moreover, overlook’s thread tension is reduced to half and threading holes are cut down by 80%, leading to less production downtime— while still maintaining a full, secure stitch. This allows the thread to stretch further with a lesser chance for thread breakage to occur, even at high speed,” said Duke Hua, Sales Director, International Sales Dept., Hikari.

He added, “For critical parts like bobbins, hooks, bearings and motors, we use high-quality Japanese components, imported linear rails and precision automation parts . That’s why our machines are more cost-effective than typical traditional machines but last longer.”

One buyer said they are particularly interested in purchasing Hikari machines, especially because of the built-in automatic thread adjusters and tension controllers.

“The automatic thread tensioner is one key advantage for us. In a multi-product factory like ours—handling everything from chiffon (90–130 GSM) to heavier fabrics (230 GSM), knits and woven garments—thread tension is a major challenge. For delicate fabrics like chiffon, georgette, viscose or rayon, puckering is a common problem. Currently, even with multiple layers, including Oxford, knit and denim, our machines handle everything, but getting the tension right is critical,” said N Vijaya Baskara Pandian, Executive VP Tech, Quality and Product Execution, Texport Industries. The company produces 1.8 million garments a month from its 20 directly owned factories spread across Bengaluru, Hindupur, Tirupur and Trivandrum.

The biggest global manufacturer of sewing equipment, Jack Technology, showcased its latest innovation, the AMH2, which featured the Vigorous Dual-Drive Motor that delivers strong, precise penetration and feeding force for continuous sewing across all fabric types. Jack also launched C5c, an overlock sewing machine equipped with zero-second thread trimming and lifting technology and Smart Rhino Feeding, ensuring faster, smoother operations without delays.

Japanese Machine maker, Pegasus, also came up with FRA Series / EXT5114-03, an automatic neck rib joint alignment device with fabric tensioners, designed specifically for processes such as attaching collars and waistbands onto T-shirts and sweatshirts. It features an automatic positioning function, which ensures stable quality and efficient operation without relying on the operator’s skill level. The built-in fabric tension roller allows ribbed elastic and body fabric to be stretched evenly and at optimal tension, enabling smooth and consistent sewing operations. Simply setting the ribbed elastic on the roller triggers automatic detection and alignment, streamlining preparation before sewing and reducing work time. This unit is ideal for high-volume operations that require precision with minimal manual intervention.

Complementing this, Pegasus SOH-Series is a fully automated unit for hemming flat sleeves, designed to deskill operations and maintain consistent quality. This machine eliminates the need for manual labour by skilled operators in sleeve hem sewing processes for items like T-shirts. Once fabric is placed, the unit performs a seamless automated sequence—automatic alignment of fabric, fabric feeding, folding, trimming, sewing, thread trimming and stacking—ensuring efficient workflow, reduced preparation time and uniform hemming quality.

“Automation is now a key focus. Buyers continue to prioritise quality, which reassures us that there will continue to be strong demand for quality products as long as leading players maintain high standards,” said John Tan Choon Chuan, President, Pegasus Sewing Machine Pte Ltd.

Oil and Lubrication Management

Effective oil management is vital for the garment industry, as improper lubrication can lead to fabric staining, increased maintenance and reduced machine lifespan. The Shanggong S60 series features a sealed oil tank with automatic pump, bevel gear transmission and dual oil return system, including adjustment screws, drain screws and magnets to minimise leakage while optimising oil consumption. Both Dürkopp Adler 910 and 911 series machines incorporate active electric hook lubrication and integrated oil systems to maintain smooth operation and minimise componentwear without risking fabric contamination. The Zoje T Master series uses a sealed oil tank with dual oil return to ensure precise, efficient lubrication of lockstitch components while preventing oil staining.

In CHNKI H360 machines, dry-head oil-free lubrication keeps stitching clean and tidy, while dual hooks reduce bobbin change frequency, maintaining consistent output without oil-related issues. The HIKARI H9VIII 7C and HW78V 35B feature oil-free machine heads, including needle bars, thread take-up bars and presser foot bars, with sealed oil pans to prevent fabric staining while supporting smooth high-speed operation.

The GEMSY G6-S3 series has an internal oil supply structure and the TYPICAL T6 Series includes a sealed oil pan to keep sewing clean, with the T6-WY model specifically featuring an oil-free thread take-up lever.

Pegasus flaunted its proprietary ‘Oil Barrier’ technology in the W600P series (3-needle cylinder bed interlock stitch machine for plain seaming; 2-needle cylinder bed interlock stitch machine for binding tape). The needle bar and looper shaft are equipped with a newly designed seal and specially developed bushing, achieving high ‘Oil Barrier’ effectiveness that prevents any oil leakage or splashes, even when the machine is idle. Maintenance is simple, including easy oil seal replacement.

Jack Technology’s AMH2, also has an oil-free head design that keeps the machine clean and ensures fabrics remain spotless.

Pocket Setters That Combine Speed, Accuracy and Versatility

Pocket setters have become increasingly sophisticated, combining automation, precision and flexibility to meet the demands of modern garment production. Today’s machines offer features such as cold folding, suction-assisted placket handling, dual independent motor drives, quick-change jigs and extended workspaces, allowing efficient handling of diverse fabrics and garment styles, from jeans and workwear to knits and non-iron materials.

Both VI.BE.MAC. and M.A.I.C.A, subsidiaries of Jack Technology, unveiled new solutions that push these capabilities further.

The VI.BE.MAC VM01 automatic back pocket setter features an innovative cold folding group that allows efficient attachment of back pockets on jeans and work trousers without pre-ironing. It is equipped with dual independent motor control, with separate motors for the needle bar and crochet, providing precise sewing control at high speed. Adjustable speed settings enable the machine to handle a wide range of pocket designs, while the quick-change jig system ensures adaptability to varying production needs. The VM01 offers a wide working area and a raisable sewing mechanism, providing extra space during operation and its extended workspace behind the sewing head allows pocket attachment in the knee area, making it suitable for denim, workwear and other structured garments.

The M.A.I.C.A UAM04 fully automatic sleeve placket setter integrates multiple innovations to maximise efficiency and versatility. It supports a wide range of sleeve placket styles and fabric types, including knitting, seamless and non-iron materials. The machine incorporates the world’s first suction-assisted automatic folding device, two workstations for high throughput, a patented needle-and-hook separated sewing head and a safe, fast automatic stacker function. Its powerful control system is complemented by a bobbin thread detecting device and an optional automatic lining device further enhances functionality, allowing all procedures to be performed on a single machine with consistent precision.

Singapore-based Focus Garment Tech introduced the VITONI AUTOMATION VT-B311 series, featuring fully automatic pocket creasers and pocket setters with rapid jig-changing capabilities.

The VT-B311-PS-FM-ACL3330 and VT-B311-PS-FM-ACL3330- FP variants handle standard and flap-equipped pockets, respectively, while the heavy-material variants VT-B311-PS-ACL3330 and VT-B311-PS-ACL3330-FP are optimised for durable fabrics. These machines automate pocket folding, feeding, sewing and stacking and include a standard VT-L fabric loosen device and optional VT-R reinforcement device. Newly designed hand-made mould templates allow local creation of new machine moulds, saving time and cost. Equipped with Brother pattern sewing heads, these machines deliver high-quality stitching and can achieve daily outputs of 2,800- 3,040 pockets in an 8-hour shift, reducing manpower requirements by 4-6 operators compared to traditional manual sewing.

“We are one of the leaders in real robot sewing—not XY machines. Compared to XY machines, the key benefits are: first, higher precision. Real robots are more difficult to program, but they achieve much greater accuracy. XY machines are simple but cannot handle certain angles or complex operations,” said Foo Toon Pow, MD, Focus Garment Tech.

Advanced Cutting Solutions for Precision and Efficiency

Cutting accuracy, speed and consistency are critical in garment production. Modern cutting systems now integrate AI, advanced vacuum systems and intelligent knife management, enabling manufacturers to handle diverse materials, complex patterns and high-volume production with minimal waste while ensuring repeatable precision and seamless integration into automated production lines.

Germany’s BULLMER PRO Mastercut All-In-One-Cutting combines multiple advanced technologies for highly precise and efficient cutting. Its core E AI software optimises cutting paths using millions of fabric-cutting data points, increasing path efficiency by over 60%, while AI cutting speed automatically analyses markers, shapes and sequences to improve efficiency by more than 40%.

The AI Knife Intelligent system uses data from over 10,000 knives to recognise force requirements and make real-time corrections, enabling accurate cutting even of thicker materials. Zero-buffer cutting technology ensures the toolpath matches exact blade dimensions, while the Ice Edge Technology allows knife sharpening in just one second. With four cooling systems maintaining -25°C circulation, the knife temperature is controlled immediately for consistent performance.

The Hurricane Vacuum System stabilises fabric hold with ultra-strong suction for continuous high-precision cutting. Additional features include continuous cutting, air-floating through-window for smooth small-piece passage, specialised solutions for down-jacket materials, ultra-fast 1-second drilling, automatic knife lubrication, inner and outer knife plate design for stable material handling and a 360 degree convenient operation frame.

The BULLMER V2 Intelligent Fabric Inspection Machine adds another layer of automation, using self-developed AI algorithms and a database of over one million defects to detect irregularities with high precision. It employs industrial-grade line scan cameras and lighting for accuracy up to 0.2 mm, with high anti-interference capability. Automatic labelling with tear-proof PET material ensures precise placement at speed up to 500 mm/s. Optional devices such as fabric feeders, discharge racks, rewinding units, cutting and weighing devices, width checkers, dust removal systems and stacking machines provide flexibility, while IOT integration and ERP/MES connectivity allow real-time inspection reporting and data-driven fabric management.

Extending the push for high-precision production, China-based JWEI’s MI 60 Multi-Layer Intelligent Cutting System focuses on speed and accuracy, running up to 100 m/minute with cutting errors below 1 mm, ensuring upper and lower layers match precisely. Its zero-buffer cutting saves up to 5% fabric. The Beckhoff AX5206 servo (manufactured by German Company Beckhoff Automation) delivers 0.01 mm control accuracy and a self-developed algorithm enables ‘cutting while moving’, increasing average efficiency by 40%. Dual-roller sharpening maintains consistently sharp blades and arc-shaped cutting edges ensure upper and lower cuts remain uniform.

Whereas, Lectra’s Valia Fashion integrates AI, cloud computing and automated nesting rules to optimise fabric usage and reduce waste, addressing complex challenges in material estimation, elastic fabrics and multi-size orders. With seamless connectivity to existing cutting-room equipment, Valia Fashion transforms traditional cutting lines into automated, data-driven operations without replacing machines or processes, ensuring precise fabric consumption, consistent quality and streamlined workflow.

Precision Fusing and Finishing Solutions

Fusing and finishing equipment has evolved to combine exact temperature control, optimised pressure systems and advanced ergonomics to deliver high-quality results while reducing energy consumption and environmental impact.

The VEIT Group, a German manufacturer of machines and systems for ironing, finishing, pressing and processing textiles, presented its latest innovations.

The VEIT FUSING MACHINE FM provides optimal adjustment of the pressure system, allowing soft, medium or hard pressing sequences and precise top-and-bottom heating tailored to the materials being processed. Improved visibility and accessibility come from a reduced machine width in the cooling belt area and an optimised viewing window, while a well-designed service concept facilitates easy cleaning and maintenance. Exact temperature control directly at the belt ensures optimal fusing, while separate feeding belts, decoupled heating zones and full enclosure minimise energy loss.

Consistent belt cleaning—both inner and outer—reduces contamination of rollers and fusing materials. The FM includes a removable feeding element for installation in confined spaces and a start-stop function that halts the input belt if fusing parameters deviate. Operation is simplified via a capacitive touch display with a user-optimised interface, remote diagnostics and service capability, while rotatable and tiltable displays improve ergonomics.

Similarly, VEIT SF 27 SHIRT FINISHER offers flexible bust sizing with a perimeter range of 780–940 mm (30.7–37.0 inches), adjustable shoulder width between 43 and 54 cm (16.9–21.3 inches), and hem circumferences of 90–170 cm (35.4–66.9 inches). Optional automatic unloading stations accelerate cycle times and increase productivity. The machine features an optimised heat recovery system that integrates advanced heat exchange technology, reducing energy consumption by up to 44%, shortening process cycles and maintaining a pleasant ambient climate with reduced radiated heat and humidity. Moisture control is managed by a unique unit that continuously measures residual moisture and the dryness of the front placket during drying. The system automatically stops the air blowing when the shirt reaches the desired dryness, eliminating operator intervention while ensuring precise and fast drying.

“The SF-27 is more flexible in shaping the shirt, including the shoulders. Unlike most finishers with straight shoulders, ours can adjust to natural human shoulder contours, improving finish under the arms. We’ve also improved energy efficiency, reducing steam consumption by around 30% compared to the previous model, though actual savings may vary depending on moisture levels and ambient conditions,” said Christopher Veit, VP, VEIT Group.

He added, “In ironing and pressing, the biggest shift is toward tunnel finishing. Previously used mainly for fashion logistics, tunnel finishers are now optimised for large-scale garment production, saving operators and improving efficiency. Finishing trends are also changing: instead of hard, crisp ironing, customers now prefer a soft hand feel, with fabrics more relaxed. Finishing, rather than pressing, is becoming the future.”

On energy concerns, Veit added that smarter, low-temperature bonding technologies are needed in the interlining industry and VEIT aims to support and collaborate on these innovations with future machine designs.

Innovations in Needles

Precision, durability and heat management are critical in industrial sewing, especially when working with dense, multi-layered materials or high-speed operations.

Addressing these challenges, Groz- Beckert, the world’s leading supplier of industrial machine needles, precision parts, fine tools and related systems, introduced the SAN™ 17 special application needle. This needle represents a significant advancement in industrial sewing, specifically designed for applications where needle heating poses a serious challenge such as bartacking, label attachment and sewing dense or multi-layered materials. This heat build-up can lead to thread melting, material damage and poor seam quality — all of which disrupt production and compromise product integrity.

“Our solution, the SAN™ 17 needle, incorporates a patented blade geometry that significantly reduces the contact surface between the needle and the material. This design innovation leads to lower friction and less heat generation, resulting in a more stable and efficient sewing process – even under high-speed or demanding conditions,” said Ralf Fritschi, Senior VP Sales – Division, Sewing and Tufting, Groz-Beckert.

Most importantly, the SAN™ 17 delivers consistent seam quality that meets the highest standards, ensuring uniform results across every stitch and it is especially beneficial for producing safety-critical and heavy-duty items such as airbags, seat belts, car seats, jeans, heavy textiles, backpacks and luggage. Another innovation the company highlighted at CISMA was INH 2.0 – a completely redesigned and significantly enhanced solution for textile manufacturers. INH 2.0 streamlines and accelerates the needle handling process, offering a more efficient workflow and improved operational transparency. Beyond that, it introduces powerful software extensions that support customers across various production stages.

With INH 2.0, manufacturers can now manage the entire needle lifecycle digitally, all within one integrated platform. They have also made major upgrades to their customer portal. The enhanced Needle Finder now covers 30 applications, helping users quickly identify the best needle for their desired seam type. The portal also features a growing Expert Knowledge video library offering practical tutorials and product insights, freely available to registered users. In addition, customer support is now accessible across multiple channels.