It’s been over two months since the first death case was reported (January 11 in China) due to Coronavirus (COVID-19), which is now declared a global pandemic by the World Health Organization (WHO). Various reports are showing its negative impact on global apparel trade too. All stakeholders of the Indian textile and apparel industry are actively concerned about various aspects of this challenge. Apparel Resources interacted with several companies from across India, exploring how COVID-19 has impacted the industry so far and how it is likely to affect in future, as well as what steps are being taken by the apparel manufacturing units for the safety of their workforce.

As far as major buying countries are concerned, as per the official data, the US apparel imports in January 2020 noticed a downfall of 11.19 per cent (in values terms) of its global imports. The major reason for the same is the impact of Covid-19. Though the official data of the EU is yet to come, Indian apparel exporters are worried about it.

Now as the epicentre of this challenge is shifting from China to Europe, Indian apparel exporters exporting mainly to Europe are more concerned about the situation. Exporters told Apparel Resources that the shipments are being asked to put on hold for one month which will further lead to delay in payments. While Raja M Shanmugham, President, Tirupur Exporters Association (TEA), is of the view that one should see it as a temporary phase and not worry much. “We should not be in a panic situation. The situation has started improving in China, so I expect that Europe as well as other countries/regions will overcome the situation soon.” He further added that China has started dispatching accessories, which is a good sign for Indian apparel industry too.

At the same time, since Japan is also suffering hugely due to the Coronavirus epidemic, Jaipur which is India’s leading apparel hub is also going to be affected in future. Majority of Jaipur’s exporters are working for Japan-based buyers, and so, they are worried in this regard. A leading exporter of the pink city Anil Sharma, Director, Art & Craft Exclusive, Jaipur, said, “So far, there is no major and direct impact on our export business from Japan, as Japanese buyers are ethical and are not cancelling current orders. But as the market is impacted there heavily, the next season is definitely going to be dull for exporters like us who are catering to Japan.”

Many apparel manufacturers do feel that uncertainty of things is one of the biggest worries for them and whatever developments are there, it will have a temporary impact. Experts believe that India should take this opportunity to put itself in the forefront of polyester-based fabric as well as cotton.

Achal Goenka, Director, Go Go International, Bangalore – a well-known apparel export company, believes, “The business impact has been both good and bad as we have started receiving more enquiries than before from our customers in fabrics/styles which were before more suitable for China. Whether it will eventually translate into orders is what we need to see. We manufacture garments from fabrics imported from China, but now that we are not sure about this fabric supply owing to the current situation, and so, we can’t take these orders. This has clearly impacted our business unfavourably.”

He further adds that trims and accessories supplies are mainly affected, as they were sourced mainly from China. However, customers are agreeing to develop the same in India. Now that the buyer would find more risk to place orders in China going forward, India has an advantage of being vertically integrated and self-sufficient in raw material supply unlike its competitors Bangladesh, Vietnam and Myanmar. However, this will benefit India short-term and temporarily.

Another important aspect in this scenario is the down sentiment of the domestic market, as the share market has also crashed. Overall buying by the customers can be slow and will impact the domestic market too. “Garment is not a primary requirement and when people have less outings to malls, cinema halls, it will naturally have a negative impact on their shopping also,” says Devangshu Dutta, Chief Executive, Third Eyesight, a prestigious consultancy firm.

Trims SME and giants are equally cautious

A multinational thread company, having manufacturing plants in India as well as many other countries, is doing a detailed survey among its customers (garment and footwear manufacturers) so it can have a fair idea about the uncertainty of the market. “This year is definitely not going to be a good year. To have minimal impact, we are trying to know the opinion of our customer and impact on their business, so we can plan accordingly,” shared a senior executive of the company on the condition of anonymity. The company has completely banned the entry of outsiders in its manufacturing facilities as a precautionary measure.

SME manufacturers are facing the challenge of the increased price of yarn and dyeing raw material, as they can’t keep much stock due to the temporary nature of this problem. Traders who used to import accessories are also of the opinion that they have not gained much so far, as whatever additional demand was raised could not be fulfilled completely due to high price and quality issues of Indian accessories.

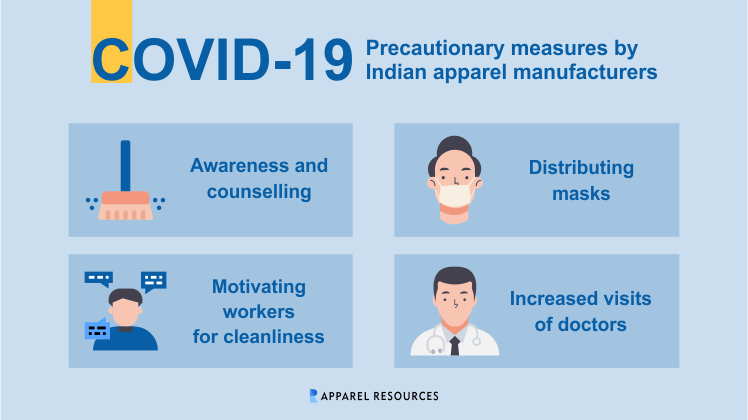

Initiatives taken by apparel manufacturing units

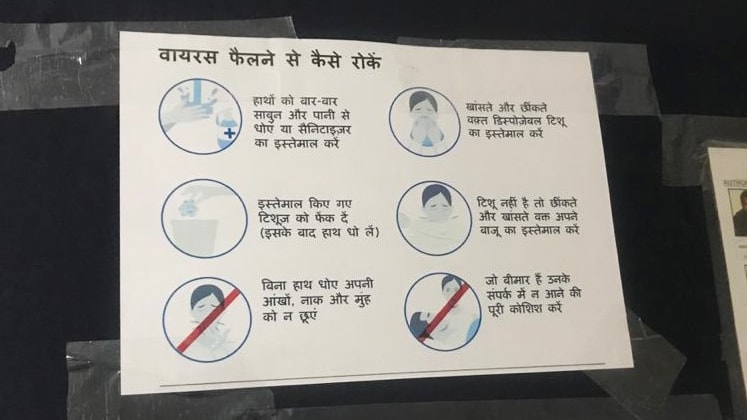

Majority of apparel manufacturing units are fully active in this regard and taking the workers and staff safety on top priority. Travel is almost banned even within India; even local meetings are mostly being held through technical tools. Awareness and counselling are on their top priority, as various sessions have been organised with workers in which HR and compliance teams, along with doctors, explained precautionary measures to remain safe. Factories have also distributed masks to all workers as well as to staff. Hand sanitisers are kept at various places in the factory premises and workers are being motivated to wash hands regularly.

Local administration is also in touch with apparel manufacturing facilities and issuing instruction too.

Orient Fashion Exports, one of the leading export houses of Gurugram, is also keeping a close eye on the temperature of workers, as HR teams are checking it on a regular basis. Rashmi Singh, Welfare Officer of the company, told, “We are also giving a mask to every visitor, offering sanitisers to them. As we counsel our workers, they are now fully informed and taking all required measures.”

CTA Apparels, Noida, one of the most respected names in apparel manufacturing, has increased visits of doctors on the shop floor, and doctors are talking to the workers frequently to motivate them about safety. HR and welfare teams of the company are closely following instructions given by the WHO and Union and State Governments, taking all necessary steps accordingly.

TCNS Clothing Company (W Brand), another well-known firm, has replaced soap cakes with liquid hand wash across all its plants. A. Rehman, Manager Compliance (Export Division) of the company, informed, “We have distributed masks to all of our employees. A training session in this regard was attended by one to all including the top-level management. Awareness messages are being announced twice a day. Even if a worker feels cold, he or she is immediately asked to contact the factory’s medical team.”