Fabric is the single biggest cost driver for the garment industry, accounting for 50 to 80 per cent of the garment cost, so even a small fabric saving of 2 per cent can add substantially to a garment manufacturer’s pockets. In this series of articles, Mausmi Ambastha, an entrepreneur providing IT solutions for the apparel industry, the Founder Director and CEO at IntelloCut, discusses various concepts and tools used in the industry to improve fabric utilization at various stages of production. These concepts help to make informed decisions and save fabric, labour and time by following the principles of “Buy what you need” and “Use what you have”. In the first article of the series Mausmi elaborates on the important aspects of Cut Order Planning.

These concepts of fabric utilization at the various stages of production help in making informed decisions and save fabric, labour and time by following the principles of “Buy what you need” and “Use what you have”. – Mausmi Ambastha

“One of the most crucial activities that take place in cutting room is Cut Order Plan. This activity is also termed as ‘lay plan’, ‘cut plan’, ‘lay lot plan’, etc. Cut Order Plan is basically optimizing the cutting process under certain constraints by following certain parameters.” Dr.Prabir Jana, Professor, NIFT, Delhi clearly defines Cut Order Plan in his article “Cut Order Planning – The Dot Com Way” published in StitchWorld July 2008 magazine. Marker efficiency, a subset of Cut Order Planning, is much hyped, as it is easily quantifiable in terms of percentage of fabric consumption. There are many facets to Cut Order Planning, and reducing fabric consumption is just one of them.

In a nutshell, Cut Order Planning is deciding the combination of markers and lays for a particular order. This is a standard process done in every factory. However, this simple decision has a huge impact on overall saving for the order.

A survey “Excellence in Global Sourcing”, conducted by Kurt Salmon in 2012, highlights that raw materials management is one of the three most important areas where firms worldwide are focusing their cost reduction efforts and Cut Order Planning is an important tool which if used properly can result in major cost savings by increasing the fabric utilization.

The objective of a good cut-plan should be to minimize overall costs. The major costs involved in the cutting room are:

- Fabric cost,

- Marker making cost,

- Spreading cost,

- Cutting cost,

- Bundling cost.

Fabric cost: Fabric is the biggest chunk of the cost and has 50% to 70% share in the overall garment cost and total labour cost is a mere 10% to 15% out of which just cutting room labour would be a much smaller fraction. Therefore, it makes sense to focus on reducing fabric cost in most cases.

Marker making cost: With the advent of CAD systems and automatic marker making systems, this task has become quicker and much more efficient and marker making costs have gone down.

Spreading cost: This depends on the following parameters:

- Total fabric laid: Every metre has to be laid by a layer man, or layering team or machine.

- Number of lays: Each new lay adds to the cost of preparation of the lay, sticking brown paper or tissue, marking on the table, splice marks, laying the marker on top, etc.

- Number of roll changes: Each roll change adds to the overhead loading of a roll.

Cutting cost: This is dependent on number of bodies to be cut.

Bundling cost: This depends on order quantity, size of bundles, number of parts, etc. Cut Order Plan does not have any major impact on bundling.

Analyzing the above costs the fabric cost is the most dominant one and it is the first priority of the Cut Order Plan.

How does Cut Order Plan save fabric?

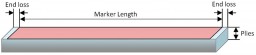

On a lay the fabric used is defined as following:

In order to minimize fabric, we have to reduce all three parameters of marker length, end loss and plies for the overall order.

1. Marker length: This concept is well understood in the industry that a higher efficiency marker results in better savings. However, if we make only one or two high efficiency markers and overlook the remnant and smaller markers, the benefit diminishes. The important thing is to focus on the overall order instead of individual markers. The reduction of Marker length for overall order can be calculated by following parameters:

1. Marker length: This concept is well understood in the industry that a higher efficiency marker results in better savings. However, if we make only one or two high efficiency markers and overlook the remnant and smaller markers, the benefit diminishes. The important thing is to focus on the overall order instead of individual markers. The reduction of Marker length for overall order can be calculated by following parameters:

a. Lay consumption is a practical and better indicator of overall consumption for the order as it takes into account the influence of all the markers over the order in terms of plies.

A popular measure used in factories is marked consumption. However, it only tells about the quality of markers and ignores their impact on the order.

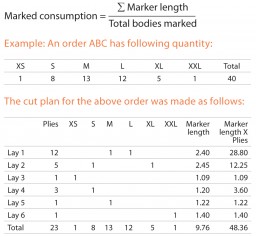

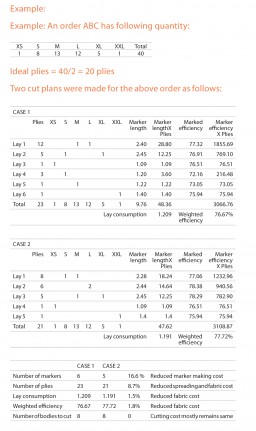

Example: An order ABC has following quantity:

Marked consumption = Sum of marker lengths/

Bodies marked = 9.76/8 = 1.220 metres

Lay consumption = (Sum of marker lengths X Plies)/

Pieces cut = 48.36/40 = 1.209 metres

The actual usage of fabric will happen based on lay consumption numbers. Therefore, this number should be used for calculation purposes for fabric requirement.

b. Weighted efficiency: The efficiency of the markers is an important indicator for the quality of markers. To estimate the quality of markers across the order, weighted efficiency metric should be used. This tells us the efficiency of the markers over the whole order weighed according to its number of plies.

In the previously mentioned article, Dr. Prabir Jana also states that “Marker efficiency, a subset of Cut Order Planning, is much hyped, as it is easily quantifiable in terms of percentage of fabric consumption.” It is the weighted efficiency of the overall order that should become our major point of concern.

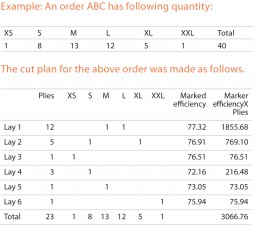

The cut plan for the above order was made as follows.

The cut plan for the above order was made as follows.

Weighted efficiency = (sum of efficiency X Plies) / Total Plies

= 3066.76 / 40 = 76.67%

Marker length can affect saving in following ways:

- Marker should have the maximum number of pieces allowed in a marker wherever possible. More pieces mixed in a marker generally results in higher efficiency and hence fabric saving.

- Marker should have an even mix of smaller and larger sizes to get higher efficiency. This will in turn deliver higher fabric saving.

- Longer markers will also result in lesser number of markers in an order thereby reducing marker making costs.

2. End loss: This parameter can be controlled by following practices:

a. A lesser number of plies in the order will result in less wastage in end loss.

b. A proper control on the production floor will help reduce end loss.

c. The end loss can be reduced by combining lays to make longer spreads.

This loss, however, is unavoidable to a certain extent but it certainly can be reduced. This topic is beyond the scope of this article which would be discussed separately.

3. Plies: This is a very important factor which is often ignored while trying to get the right mix ratio of the order. Let’s see the impact of number of plies with a simple case.

Say, Marker length = 10 metres,

Cut-able width = 1 metre

Marker efficiency = 80%

Total ply area = 10m X 1m = 10 sq. metres

Fabric area utilized in garments = Efficiency X Ply area = 0.80 X 10 = 8 sq. metres

Wastage per ply = 10 – 8 = 2 sq. metres

This means that 8 sq. metres of the marker will be actually used for cutting garments and 2 sq. metres will be wasted within the marker. Every additional ply put on this marker will result in wastage of 2 sq. metres of fabric and some end loss as well.

It is clear that the higher the plies more the wastage.

Therefore, to save fabric and avoid the above wastage,the number of plies should be as close to the ideal plies as possible.

There is a simple formula that explains the calculation of ideal plies for an order. Ideal plies is the least number of plies which is required to cut the whole order under the present constraints.

The marker maker can put maximum 2 pieces in a marker.

Ideal plies = Order quantity / Max. pieces allowed in marker = 40/2 = 20

Therefore, a cut plan with 20 plies should be the ideal solution.

It is always possible to create a cut plan with ideal plies for any order quantity or ratio. It is a matter of doing tedious calculation and trying all possible solutions. As the order quantity and ratios increase, it becomes more and more difficult to arrive at the ideal plies. For the simple example as above there can be more than 10,000 possible solutions. A good software should be able to do these calculations and arrive at the best possible solution.

The number of plies can affect saving in various ways.

- Wastage in Markers: Every additional ply put on the markers will result in wastage of fabric within the marker owing to its efficiency and some end loss as well. The number of plies should not vary largely from the ideal plies for better fabric saving.

- Each additional ply results in higher spreading cost as well.

The number of plies actually used will increase slightly from ideal numbers due to remnant markers. However, a factory can always monitor the variance percentage from ideal plies.

A good Cut Order Plan should have following characteristics:

A good Cut Order Plan should have following characteristics:

1. It should use ideal number of plies and only increase some of the plies owing to remnant markers.

2. It should have as many markers as possible with maximum number of pieces allowed in a marker. The markers should have a good mix of smaller and larger sizes. They may have few smaller markers which should be made only in the case of remnant markers.

If the following two objectives are met, the cut plan will result in a lower lay consumption and higher weighted efficiency, reducing overall cost of the order. Two cut plans can be compared based on number of plies, lay consumption and weighted efficiency to determine which one is a better solution.

Both the solutions shown above look equally plausible and correct. However, on close examination we can clearly state that the second case is a much better solution for reducing overall cost of the order.

A survey “Excellence in Global Sourcing”, conducted by Kurt Salmon in 2012, highlights that raw materials management is one of the three most important areas where firms worldwide are focusing their cost reduction efforts. Fabric being the major raw material is an important area of cost reduction efforts and Cut Order Plan is one of the tools which, if properly used, can result in major cost savings.