Gandhi Nagar(Delhi), Ballari(Karnataka), Ulhasnagar(Maharashtra), Ahmedabad(Gujarat) are known for jeans manufacturing. Naturally developed clusters; cost-effectiveness; having own units as well as dependency on job work and migrant workers; majority of working in unorganised way; supplying through wholesalers and dealers; lack of basic infrastructure, ample business opportunity… are some of the common threads among these clusters. Though over the years, there have been few improvements observed in these hubs, still overall nothing has changed much. These hubs are making around 80 per cent jeans for Indian domestic market.

Gandhi Nagar: Leader in fashion

This cluster alone houses more than 5,000 manufacturing units with 10 or more machines, averaging around 20 machines per unit and consuming around 5 million metres of denim fabric per month. More than 3,000 wholesalers and around 500 small and big brands work here day and night to feed the nation with fashionable jeans, but only a few have their units.

Majority of denim that this cluster produces are of polyester base and have funky designs. Creativity and excellency in fashion are some of the biggest advantages of the hub and it also has the support of washing in areas like Loni (Ghaziabad) and Badi (Sonipat).

As this hub offers the entire range of garments in endless variety, denim manufacturers also get the advantage of huge clientele and visit of countrywide retailers. Spread almost in the vicinity of 15 kilometres and in various other areas like Tank Road, Karol Bagh, thousands of micro and small units are involved in the various activities of jeans manufacturing. These areas offer an entire range of denim, top as well bottom for men, kids and women.

One of the big advantages of Gandhi Nagar and other allied areas of Delhi is that many jeans manufacturers are not only producing jeans, but they are also into trousers and shirts. It gives them the added advantage of a large client base.

Also Read: Expansion Taking Place Again! Emerging Hubs Are The Preference

Ballari: Average growth as washing needs to improve

The well-known jeans production hub of South India, Ballari offers employment to around 70,000 people as the hub has around 500 jeans manufacturing units. Along with the domestic market, the hub also exports denim products to few countries like Sri Lanka, Singapore and Dubai. Denim fabric and accessories come here from Ahmedabad and Surat.

Core products of the hub are bottom for men and kids while few are also producing denim for girls and women.

The hubs works like a cottage industry and thousands of people produce jeans at their home with few machines till the point of final finishing and packaging reaches. The majority of factories, as well as people at home, are using Chinese machines while few factories are using branded machines too.

The hub has the advantage of local workforce and only a few migratory workers are there in washing units only. But it is lacking behind on the quality front especially as far as the wash is concerned. The hub survives as it offers products on credit and caters to the main states of South India like Karnataka, Andhra Pradesh, Tamil Nadu, Kerala and Telangana mainly.

Pollux Mallikarjuna, one of the leading jeans manufacturers using Vibemac machines told Apparel Resources, “Due to Covid, still the majority of manufacturers have stock with them and until this stock doesn’t clear, no new initiative can be planned.”

Ulhasnagar : Manufacturing culture of the city

Having the benefit of proximity with Mumbai, Ulhasnagar (Thane district) supplies jeans across the country but its core market are Maharashtra, Gujarat, Chhattisgarh, MP and some cities of Tamil Nadu. Using mainly cotton base and producing sober designs makes Ulhasnagar carve a unique niche for ityself. Lycra, Lenin and other variety of fabrics are also being used here. Around 1 lakh people are employed in jeans manufacturing activities in this hub and 300 good units are functional. Along with Surat and Ahmedabad, this hub also sources denim fabric from Bhilwara.

Some of the local firms are exporting jeans to South Africa, Nigeria, Dubai and Kuwait.

Vishal of Womenzo, Ulhasnagar told that apart from being a jeans manufacturing hub, Ulhasnagar is also into the production of footwear, plastic-based packaging material and some other things. The city has a culture of manufacturing. Using a variety of fabrics in denim bottom, Womenzo offers jeans for men, women and kids also.

Ahmedabad: Strength of local fabric availability

Ahmedabad is the only hub of India which has giants like Arvind Ltd. and also hundreds of SME jeans manufacturers. The biggest advantage of the hub is local fabric sourcing as there is abundant denim fabric manufacturing in the city. Not only big mills but also medium-level denim fabric producers are there and their rates are also less compared to big mills. Even some such SME denim fabric producers have width of 70 inches in their fabric which is around 5 inches higher than mill fabrics.

There are at least 800 firms involved here in jeans business and in-house and jobwork ratio is around 30:70. The city supplies jeans mainly to Gujarat, Uttar Pradesh, Madhya Pradesh, South India and few other states of India.

Along with bottom, Ahmedabad’s many players are also producing denim shirts, denim tops and so on. With direct contact, this hub also exports jeans to Middle East countries.

“Ahmedabad is known for its quality and fitting as the hub hardly has size issue,” said Ravi Patel of Ego Clothing who has an in-house set-up of 30 machines (Juki and Brother).

Wholesalers and Dealers network is the key

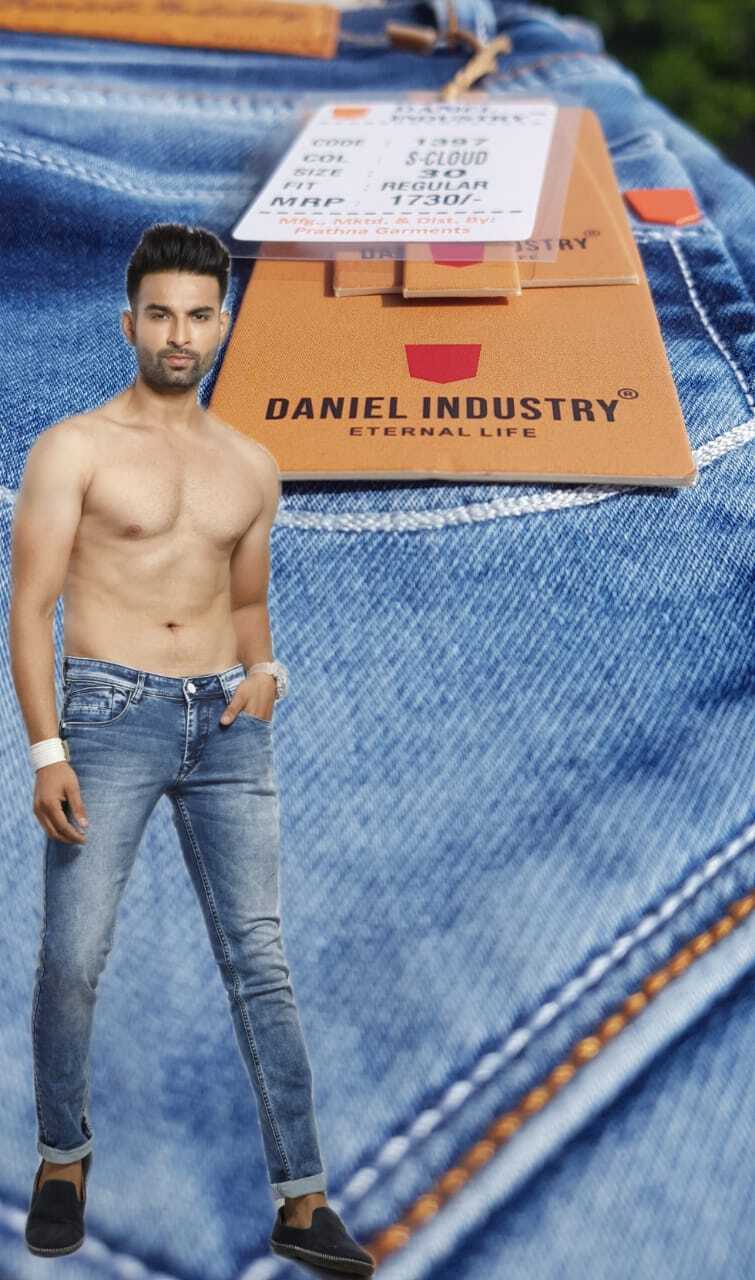

All these hubs majorly supply jeans through wholesalers and dealers as this traditional way is easy to work and also ensures their payments. But there are some firms in every hub that prefer to work directly with retailers. “Directly supplying to retailers saves the commission of wholesalers and dealers. It makes us cost-effective also,” says Sanjay Masand of Daniel Industry who is also having his own store. The firm is mainly into premium quality jeans and offers more sizes compared to many other firms.

Most of them are so involved in their existing operations that they can’t focus much on further growth or new avenues. Very few of them have their own websites and are not even promoting/updating themselves on social media.

Unorganised even illegal… impact business

Though over the years, overall working of all these hubs has improved, some of the manufacturers have set up reasonably big units and strengthened their brand or are working with retail giants. Still, all these hubs have majority of unorganised units and some of them are even working illegally. Though it helps them to be cost-effective but they can’t survive in long run as action against such units is a routine affair for Government officials also. This builds a negative impact on the image of the hub also. To avoid such a situation along with the initiative of local players, Government support is also a must.

“After a court order to shut illegal jeans wash units, several units shifted to other cities and the State Government is not listening to our demand to set up Maharashtra Industrial Development Corporation (MIDC) area in the city,” said Dinesh Lahrani, President of Jeans Manufacturing Association, Ulhasnagar.

Quality is another area where the majority of the players need to improve. Though these players are under heavy pressure to offer cost-effective products as intense competition is there but at the same time, many firms are doing good business just because of good quality products. The majority of the players of these hubs are using surplus fabric which also sometimes creates quality issues.

Further growth expectation

Challenges that have already been prevailing to various time-bound challenges like Covid have hurt the growth of these hubs and maximum players of these hubs are just surviving, not achieving good growth. The irony is that there is no proper strategic planning and Government support is also not there. The natural growth of the economy, rise in demand are only a few supportive factors for these players.

“There are various schemes of Government for SMEs but we can’t take advantage of most of such schemes due to the stringent rules and our unorganised working system. So policies have to change in a way that we as well as our jobworkers can take benefits of these schemes,” said Tapasvilal C Jain, President, District Jeans Garments Merchants Association, Ballari.

He further added that Government support is required more on the export marketing front as small players of such hubs like Ballari can do better in export to small countries and SME buyers who just ask to follow law of the land rather than indulging in complicated compliance and certification. Tapasvilal’s firm Paxal Fashions is also exporting jeans to Sri Lanka.