Tackling the adversities of the pandemic, five leading material manufacturers came together to launch the innovative JUST5 jacket in August this year. All components of this jacket are individually available for any apparel or home textile brands to create their own innovations.

Carlo Centonze, Co-founder and CEO of HeiQ Group, while introducing the innovation, mentioned that this is HeiQ’s first commercialised high-tech garment. He emphasised that any brand can simply take parts from these suppliers and make their own 100 per cent ‘viroblocked’ garments. Ronan Cox, President, Performance Materials, Coats, said, “Together, we have demonstrated the power of industry collaboration. By pooling our expertise, we have developed a solution to the challenge of people not only wanting to restore normality to their everyday lives, but also be protected. Coats is passionate about innovation and is proud to be part of this ‘first in garment’ technology.”

Also Read: Athleisure is rewarding in USA, shows import growth of 9.73% in leggings

The jacket appoints self-sanitising 2A-NYGUARD NYSHIELD zips, Coats ProtectV sewing thread that have anti-microbial and anti-viral properties, SITIP warp-knitted fabric to lend elasticity to the jacket, and Windtex Vagotex fabric that is a breathable, water-repellent and wind-resistant fabric. Windtex Vagotex S.p.A. is a leader in lamination and processing of technical fabrics for sports and footwear. All in all, this jacket is futuristic and brings to light fabrics and material that are just right for the times we are dwelling.

While this is a breakthrough, Indian brands too are not stepping behind. In fact, most brands within the athleisure domain are relying on local manufacturers for their fabric and fibre requirements. Innovation, they believe, starts on the drawing board, and it is high time to bring up the local industry.

Why look beyond borders?

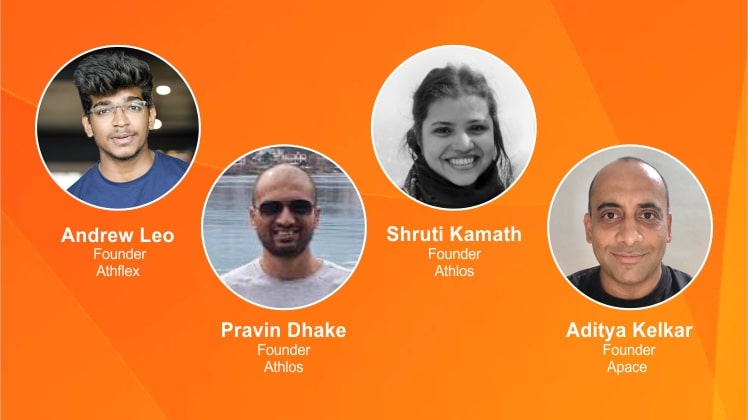

“Today, Surat has a list of manufacturers who are ready to experiment with their offerings in order to suit the evolving lifestyle needs of consumers. We, at Athflex, experiment with a wide range of fabrics in casual and sportswear ranging from cotton, linen, polyester, and rayon that suit the requirement of every individual. We create sweat-absorbent outfits so that you have a concentrated mindset while initiating those fitness moves,” informed Andrew Leo, Founder Athflex.

Athflex manufactures breathable sports clothing made up of spandex, polypropylene, wool and polyester blend. “Winter sports activity needs you to be warm and sweat-free. Hence, we create special winter based sportswear that are breathable and evaporate sweat immediately. Even if you are involved in heavy workout and don’t get enough time to wipe up your body, our skin-friendly range of athleisurewear would spontaneously take care of you,” Andrew added. Their entire manufacturing is done in India, and Andrew and his team are experimenting with manufacturers to launch a seamless range for women real soon. What sets Athflex ahead of the others in the category is their competitive pricing and the brand’s ability to retain an international quality make within a reasonable price bracket.

Understanding customer needs

In 2015, Athlos, an activewear brand, was launched. At that time, the major players in the industry were either focused on chasing fashion trends or branding jargon, Pravin Dhake, Founder, Athlos pointed out. “Neglecting the core of design and comfortable performance fabrics. Our founding principle was driven with a focus on sustainable fabrics and clean aesthetics. At the start, we launched with a single anti-odour T-shirt design made from bamboo fibre. With time, as we started understanding our users and their needs better, we introduced more fabrics to address their problems and built our portfolio. Your customers will always be the best feedback for what you need to do next. Initially, we launched products suitable for cross-training and running over shorter distances. As our customer base increased, we had a lot of runners asking for a running collection, and we launched our distance running collection,” Pravin added.

“Sustainability has always been at the core of our innovation. Since going live in 2015, we have launched a variety of sustainable fabrics including bamboo, eucalyptus, Econyl made from recycled ocean waste, and Merino wool – each fabric solving a specific user segment need. Besides being sustainable fabrics, we were also able to reduce our dependence on virgin synthetic fabrics. For example, using Econyl allowed us to introduce a high-performance fabric in our running collection which is completely recycled, as opposed to 100 per cent virgin polyester fabric used in mainstream running gear,” Shruti Kamath, Founder, Athlos, mentioned.

“With our knowledge of fabrics and understanding of fabric performance, we are currently in the process of developing a menstrual product combining our multiple fabrics. You would be able to see the product before the end of this year. At Athlos, mostly ideas and use-case definition have led us to innovate new fabrics. Interestingly, there have also been exceptions. For example, we were excited about the possibilities of our Merino wool and how we can use it that lead us to blend it with eucalyptus fabric and design all-weather baselayers for our outdoor collections,” she added.

Also Read: Basic T-Shirts to athleisure: Trend is shaping up and so is technology

Making it work

“Apace is a performance apparel brand focused on endurance sports. Running, cycling and triathlon comprise our main target segment. Initially, during product development, we studied what existing brands were doing in this segment. Performance products need to have a specific type of performance from the fabrics such as wicking action, stretchability, durability, and wear resistance. Also, due to triathlon, the fabrics needed to be able to get rid of water quickly, and also not hold water while swimming. Also, availability and cost were factors to be considered. We approached the problem in a phase-wise manner, and kept making improvements to the fabrics we used. Being in a niche segment, and competing against established international and domestic brands, we had to make sure our products were relevant to the Indian customer, were not a burden on the pocket, and also provided value adding features. Once we got our basics right, we went about innovating, since we had a good understanding of the target segment, and its functional and aesthetic requirement,” informed Aditya Kelkar, Founder, Apace.

“By using elastane-based fabrics (spandex, spandex meshes) at the right places in our products, our innovations challenged the status quo and have provided functional features for the cyclist, runner, and the triathlete. We also focused on keeping the products as local as possible, thereby reducing our dependencies on imports. Our product designs consider this aspect as well, and we constantly try to develop alternative designs using accessories and material that can be procured locally. Other than certain accessories that currently need to be imported, we are proud to say that our products are 90-95 per cent locally sourced. Our focus is to make the best use of the fabrics that we already know well in designs that leverage the properties of the fabrics to the fullest. It is a combination of both – ideas promote innovation in fibres and fabrics, while availability of more options in fibres and fabrics creates the opportunity for more products and ideas,” Aditya further added.

Also Read: Every bit counts: Redirecting fabric waste to craft new products