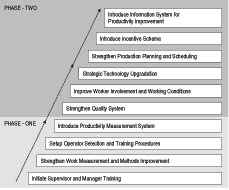

To achieve a quantum jump in productivity, preset notions about a productivity paradigm has to be dispelled. The manufacturing practices and maturity of the management in handling various tools to improve productivity are likely to vary in order to address the specific needs of their organization.

Initiate Supervisor and Manager Training

The apparel industry is quite conservative in providing training to its supervisors and managers. Manufacturers look for experienced staff to avoid training them. Experience, though important, needs to be supplemented with the latest scientific skills and know-how, for improvement in productivity. Apart from creating in-house capabilities for imparting training, companies must also send the supervisors and managers for specialized training programmes to learn scientific methods of line balancing, plant layout, work place engineering, planning and scheduling, motivational measures, man-management, etc. Visits to progressive apparel manufacturing plants and technology shows also help. Apart from these, supervisory staff also need continuous inputs on market realities including competitive scenario and consumer expectations to be better prepared to respond to current market needs.

Training is a continuous process. It is vital to groom in-house trainers with the help of specialists so that organizational know-how and capabilities are built over a period. This will also help provide need-based training to employees. In many progressive organizations, training has been integrated with career progression of the employees. They have to attend training modules and pass examinations to be eligible for promotion. It is also recommended that the companies provide induction training to all its new employees so as to familiarize them with the work culture and the organization’s ethos.

Strengthen Work Measurement and Methods Improvement

Think there must be a better way

The existing know-how on work measurement and methods improvement prevalent in the industry is limited and inadequate. Factories rely more on past performance to set production targets, rather than calculate the work content of the operations using established procedures like time & motion study or pre-determined time standards. Factories that use these scientific methods have benefited in terms of productivity.

Out of the total time spent by a sewing machine operator, on an average, only 20% time is spent on actual sewing and 80% is spent on various allied activities. The objective of work study initiatives has to be to maximize the proportion of actual sewing time in the total attended time by an operator. Methods improvement can play a major role in achieving this objective. As the maturity level of the ‘Work Study’ team increases, a full-fledged Industrial Engineering Cell can be created. This will ensure continuous efforts towards methods improvement, reduction in waste and justified time standards. The cell could also integrate application of Ergonomics for productivity improvement, worker comfort and safety.

A study shows 6 to 15% productivity improvement in select operations by introducing adjustable height in tables and chairs for workers. With the IE Cell in place, factories can achieve higher productivity with same or lower resources.

Setup Operator Selection and Training Procedures

It is crucial to recruit a person who has the right aptitude, attitude and ability for a given job.

These tests ensure that people with the potential to produce the desired level of performance are admitted to the plant and the factory does not spend valuable time and training resources on unsuitable candidates.

As regards operator training, a large section of the industry feels that recruiting experienced operators is a better option, yet many progressive manufacturers have setup their own in-house operator training cells. Productivity performance of these factories is found to be much higher than factories with no operator training. The training cell should also be equipped to impart need-based skill upgradation training. Experience of American factories shows that in about 12-13 weeks, trainees can attain 80% efficiency on most operations. Highly skilled operations need a longer period, eg , 16-18 weeks.

Introduce Productivity Measurement System

A productivity measurement and comparison system for productivity improvement is aimed at capturing production data from various workstations at a predetermined frequency. Trained personnel should process and analyse the data to generate productivity reports for specific operations, machines, operators, sections, production lines and the total production floor. The system should generate productivity reports in physical productivity terms, as well as percentile efficiency, vis-à-vis standard performance. Once generated, the results should be shared immediately with various stakeholders, i.e., production workers, supervisors and executive staff.

A productivity measurement and comparison system for productivity improvement is aimed at capturing production data from various workstations at a predetermined frequency. Trained personnel should process and analyse the data to generate productivity reports for specific operations, machines, operators, sections, production lines and the total production floor. The system should generate productivity reports in physical productivity terms, as well as percentile efficiency, vis-à-vis standard performance. Once generated, the results should be shared immediately with various stakeholders, i.e., production workers, supervisors and executive staff.

It is easier for an apparel manufacturer manufacturing basic product to maintain quality, unlike for a fast-fashion apparel manufacturer manufacturing small quantities with fast changing styles, highlighting the need of a ‘process oriented approach’ to quality.

The next important aspect of such a system is the mechanism for productivity performance review of the plant. Involvement of the workforce in the improvement process will help immensely. This process will involve analysis of reasons for productivity gaps and suggest specific measures to be taken to bring in improvement.

Once these enabling practices are in place, productivity measurement system can be operationalized. At this stage, the inputs needed for smooth running of the system are garment analysis sheets produced by the industrial engineering team, line planning, job allocation and production schedule. These inputs will be used in actually operationalising the production line and communicating production standards to the work force. As the enabling practice will be in place and inputs are provided to the system, the organization can now get the desired output i.e. productivity reports at different levels, insights into productivity gaps and remedies.

Strengthen Quality System

Analyses of the business practices followed by the apparel manufacturers with productivity, twice as high as an average apparel manufacturer, clearly indicate that most of the factors associated with higher productivity are controllable. Therefore, if the management of an apparel manufacturing organization is sincerely committed to productivity improvement, it is certainly possible to achieve substantial gains by controlling the factors affecting productivity.

In most factories, the focus of the quality function tends to be on defect detection prior to the dispatch of shipment to the customer rather than defect prevention. Managers tend to overlook quality defects in the merchandise in order to meet the delivery schedules. It is also observed that, only in rare cases, the quality performance of the factory is analyzed in terms of success/failure rate of shipments, defect rate trends, frequency of defect type in total defects, causes of the defect and remedial action taken to prevent these defects.

If an apparel manufacturer specializes in basic or staple apparel products, managing quality becomes easier, compared to high fashion products with small order quantity. As the product keeps changing very fast in business of fashion, the firms have to adopt a ‘process oriented approach’ to quality than a product-specific approach. The process model, advocates the need for each work group in the organization to be made ‘process capable’ so as to meet the needs of quality assurance in fashion apparel manufacturing. The model stresses on five elements needed for a work team to be process capable, viz., motivated work force; know-how; skills; training and plant and machinery. It is the responsibility of the management to understand the principles governing the process model, and to ensure that all the work groups responsible for various processes are ‘Process Capable’.

Improve Worker Involvement and Working Conditions

Workers can play a vital role in planning and implementing improvement programs. However, very few factories understand the importance of the worker involvement.

“Involving workers in the process of change has several advantages. If workers have a good understanding of working methods or systems, there is likely to be a greater degree of commitment and motivation and consequently higher productivity level.”

Whether you buy expensive, modern ironing equipment or simple second-hand sewing machines, their use can only be enhanced by the cooperation of informed, trained and motivated workers. It would therefore be advisable to involve workers in selecting and installing the new machinery. Attempts to improve working conditions will make workers feel that you are concerned for their well-being. It is often surprising how small improvements are appreciated far beyond the time and money invested.

Another good reason for involving workers, particularly in developing and implementing change, is that people are more likely to support an idea which has come from them. Workers may thus become committed to further problem-solving and be prepared to cope with future changes more flexibly. A third good reason for involving workers is that they have valuable information which can be precious to you. We often forget that they are “experts” in their own workplace and fully acquainted with raw materials, machines and working processes. They can contribute, if given the opportunity, to many areas with the enterprise. “

Apart from the worker involvement in improvement, safe working conditions are a must for world-class performance. A safe place of work takes away the fear of accidents from the worker’s mind and they are able to perform with greater confidence. Every country has rules and norms towards ensuring health and safety of the workers in the factories. These need to be adhered to not only as compulsions, but also as innovative best practices used by factories to galvanise the initiatives taken by the factory to bring in improvements in this direction.

Strategic Technology Upgradation

‘Strategic’ for the reason that the initiative must be aimed at meeting a strategic objectives of the organization which would further improve the competitive edge of the organization.

The following steps, developed using the framework shall be useful to companies to draw up a technology upgradation plan:

• Identification of bottleneck operations/processes and operations needing extremely high skills. These operations/ processes tend to restrict performance and that is why need to be given preference in the upgradation plan.

• Assessment of the current level of technology in various departments is critical. It is important to strike a right balance between this standard of machines and other specialized machines.

• Assessment of the technological expectations of the main customers. The specific requirements of leading international buyers do influence the technology levels adopted in the factories of their suppliers. Certain level of technology may become a must to be able to produce for certain buyers. These technological solutions can be termed as ‘Order Qualifiers’. There could be certain equipment, which may add to the technological appeal of the plant and can be termed as ‘Desirable’.

• Review the modern technological solutions available in the market. Many progressive apparel manufacturers across the world tie up with technology developers for collaborative developments or testing new solutions in their plants.

• Once the upgradation implementation starts, it is vital to carry out a periodic review of the absorption of the new solutions and the resultant performance improvement. Results of the review process of the technology absorption may provide certain inputs for fine tuning the overall upgradation plan.

New technological solutions bring with them the need for new capabilities among the maintenance team. Most apparel manufacturers use mechanics as trouble-shooters or fire-fighters. But an efficient and effective maintenance program is much more than repairing the malfunctioning machines. A well planned preventive maintenance program, will not only ensure that machines are repaired in quickest possible time but it will also bring down the machine failure rate.

Strengthen Production Planning, Scheduling and Control

Generally, it is seen that workers have to shoulder the blame of low productivity for reasons beyond their control. Large amount of productive time of workers goes unutilized, due to loopholes in production planning and scheduling. Possessing a management team equipped with better technical and man-management skills, well trained operators and productivity measurement systems, all help in strengthening production planning and scheduling. The aim should be the maximum utilization of the productive resources of the factory. Fashion apparel production is a dynamic business with constant changes and it needs a dynamic production planning, scheduling and control system.

It must also be noted that as the optimal performance level of productivity comes closer, the relative effort needed to bring in improvement goes up. It is important that factories, at this stage, seriously evaluate information technology based systems for this purpose. Many software solutions are available for various needs, scales and price points.

Introduce Incentive Scheme

Gains in productivity will not be sustainable if the workers and the staff do not reap the benefits of higher productivity. As the factories are likely to have already gained substantially through implementation of the recommendations on productivity improvement, it is the right time to draw an incentive plan for the work force which encourages higher performance and rewards it suitably.

The principle governing the payment system should be ‘fair day’s pay for fair day’s work’. When the management expects world-class performance from the workforce, it should be ready to reward such performance in a fair manner. A hundred per cent or standard performance as per British Standards can only be achieved with an incentive-based payment system. In a non-incentivised system, the expected ‘Standard Performance’ goes down to 75%.

An incentive-based payment system should be able to address the following points:

1. The system should not only motivate workers to produce more, but also to provide better quality.

2. The system must be transparent, fair to all, and easy to understand.

3. It should result in a win-win situation for workers as well as the organisation.

4. It should not be too complex to operate.

5. It should be aimed at overall productivity improvement of the plant, rather than performance of certain individuals.

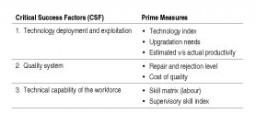

Introduce Information System for Productivity Improvement

The key to success of the implementation of any productivity improvement strategy is active support of the top management. At the same time, it is vital that the top management/CEO receives constant updates on the status of the factors critical to productivity improvement. The Critical Success Factors (CSFs) (Table above) approach developed by Rockart at the Sloan School Of Management, MIT, can be effectively used to identify CSFs to productivity improvement. If the organization can ensure that regular update on CSFs is available to CEO, he will be able to take faster and better decisions.