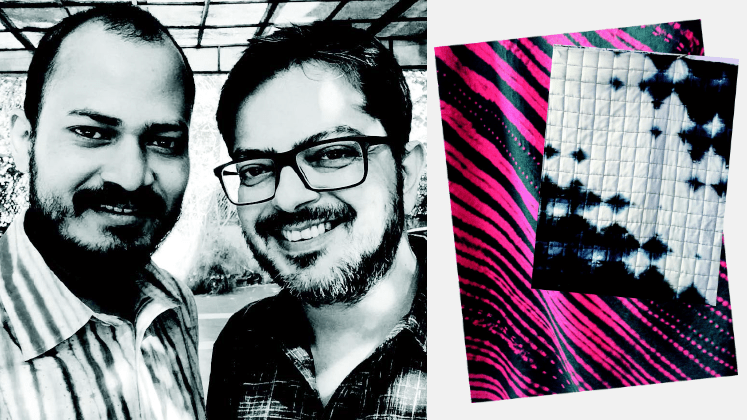

Responsible for fashioning shibori prints in Indian fashion, Amit Vijaya and Richard Pandav’s, namesake brand Amrich, celebrates a union of fine natural fabrics, sophisticated cuts and smart tailoring laced with tradition.

Coming from different backgrounds and cities, fate did have a role to play when the designer duo joined forces while studying at National Institute of Design (NID), Ahmedabad. With several industry experiences, fashion platforms and projects later, the duo found their true identity in Amrich, the label.

The essence of the label champions hand-done surface techniques such as tie dye techniques, shibori, hand block printing, bandhani, mud resist printing, etc., bringing different aesthetics to the table. Amrich is a confluence of two contrasting perspectives that translate beautifully into elegant pieces.

AR gets candid with both Amit and Richard as they open up about their inspiring journey, the things they learnt – and the ones they wish they could unlearn – and what it takes to turn a dream into reality.

AR: Both of you come from very diverse backgrounds wherein design was not your first choice of education. How did the transition take place?

Amit: We both are from very diverse backgrounds. He did his graduation in IT and I did my graduation in botany and I was struggling to the point where I didn’t know where I would go and what I wanted to do, like all other youngsters these days. I was generally good in studies and stood 12th in Mumbai University in my graduation.

After graduating in Botany and Horticulture, I got through Cornell Miami State University but dropped out after one year because I found it very boring. I was unsure of what I wanted to do further but then luckily, my father was setting up a graphic unit in Kolkata, where there were computers being put up and he asked me to help out. So I moved back to Kolkata from Mumbai.

I was involved actively there in client servicing and it was exciting to know what the client really wants and then try to fulfil their expectations. It was satisfying. What’s funny is when I now look back at it, I feel that destiny plays such a big role because most of my clients there turned out to be in textiles and apparel in Kolkata, without me going out and looking for them.

Richard: I studied IT for four years but in the fourth year, I decided that I can’t do it. I had a friend in SEPT who was studying architecture and I asked to him whether he thought I could do anything creative. Small things like me picking my mom’s saree or helping my sister in dressing hinted towards a creative bent. My friends therefore suggested NID to me, I went and filled the form, in fact I took help to do so because the NID form is really hard.

I was called for the interview and I got selected. In the first semester Amit and I became friends – he was in textile and I was apparel but our first foundation course on Color and Composition was together and that’s how we came together.

AR: How did you get into textiles and more importantly, the shibori/tie and dye craft?

Amit: I was told that I have an eye for textiles and represent textiles, but it still hadn’t sunk into me whether I wanted to get into textiles. An exhibition called Sutra that spoke about trading textiles from India to all over the world, happened in India at that time. I was hired as a graphic designer for them to do their brochures etc., and that’s when I got to learn about our heritage and the spark got ignited.

It’s there where I met Archana who is like an elder sister to me since she is the one who actually told me that I have a knack for textiles and I should take it up as further education. I was 26 then and I didn’t know if studying was an option; I was playing around with textiles in different organisations and then I thought maybe I should give it a try.

Shibori is very common today but in the ’90s, it wasn’t there in India that much – only two or three textile studios were doing it. Archana didi came up with the idea of doing an event on shibori I had no idea what shibori was. It’s true that I was doing graphics for prints, but shibori was completely new for me. One of my friends told me that it is nothing, but similar to India’s way of doing tie and dye.

I therefore started dabbling with shibori at home by taking my mom’s sheets and cutting them. For me, fabric was sacred because it was always expensive; so I used old sheets, handkerchiefs and cut them up and tried doing a little bit of tie and dye; it was magic. I used to stay up at night working in the kitchen to try and see what kind of things come out and one day I took all of it and dropped it in Archana didi’s lap saying this is what I created. She immediately said that “you have to go to my factory and instead of doing this, take silk scarves and do this on them.” So I did a few scarves with shibori and a Japanese buyer came and purchased all of them and ordered even more pieces.

Because I was not somebody who trained or read books on how to do shibori, it was a lot more spontaneous and creative than the regular shibori which was what people liked.

Archana didi was still adamant that I study textiles; so I filled up NID form thinking I won’t get through, but I was called in and I joined there as a textile designer. That’s the whole story.

AR: Both of you bring different creative influences to the table which is the reason behind Amrich’s success. How did you two come together?

Amit: While we were at NID, we had similar aesthetics but he (Richard) is more about opulence, maximalism while I like the exact opposite and would pare it down. We thought we will go out in the industry separately and then maybe combine in the future to start a label of our own.

NID is very close knitted. One day we were at the apparel studio helping Rahul Mishra – who was preparing for Lakme’s Gen Next programme. The following season, Rahul urged us to apply to keep up the tradition of NID students participating in Gen Next. As a textile designer, I couldn’t apply separately because I don’t know apparel that well, so that’s when we both combined our forces and the rest is history. We showed at Gen Next with rave reviews. We were in our third semester then, and started getting calls from stores asking to stock us. We had done one piece of each style and we didn’t know the business of fashion as such but instead of chasing the fashion dream, we decided to come back and finish our semesters.

AR: How did you guys start out and create Amrich – the label?

Amit: Many students think that fashion is all about glamour but that lasts for about five seconds and the rest of it is something that you’d have to work a lot for. We didn’t want to have no experience and only stick to fashion weeks, so we thought of doing projects where both textile and apparel designer are needed because that would be the true test of whether we can work together in future or not.

We worked with Khadi Gramodyog in Gujarat with their old stock and made garments which costed not more than Rs. 500 and sold it for Rs.1000, which was a real challenge. Once we finished our graduation, we got a call from Ravissant Delhi, for their couture house which is very unheard of. They hired us as team for one line on a 6-month consultancy and those months went so well for them that they kept extending the contract and eventually it extended to 18 months. We did high-end couture for them, with a lot of embroidery work, bridal trousseau and stuff and it also involved meeting the who’s who of the country.

Richard: There came a point where we realised that we can’t do this forever. I remember it was Diwali in October 2010, and we were sitting in Amit’s house in Kolkata when I told him that maybe it’s time to start our own thing. He agreed and that’s when we decided to quit.

We came back to Delhi after Diwali and we knew a master who had three tailors in his unit, so we asked him to work with us. At that time, we worked from home doing our dyeing at home as we didn’t need a big industry type of unit. We did a lot of shibori textiles, designed them and then gave the garments for stitching – this took about two months and by December-end, we had a line of about 30 pieces ready. We had a friend who lived in the hills and she was going home, so we thought of accompanying her to shoot our clothes, make a lookbook and then send it to five stores. I remember, Ogaan reverted back within half an hour of receiving the mail.

In 6 months since our launch, we were retailing at 30 stores. After two years, we realised that among the 30 stores we were retailing at, there were only 7 that could understand our aesthetics and afford to pay the money for our craft – so we downsized. Today, we are retailing in 10 stores in India who we have been with us for more than 6-7 years.

AR: What would your advice be to labels who have just started out?

Amit: I think a lot of labels are created when students pass out of colleges and start their own label on their father’s money; these lack a distinct identity and hence are difficult to survive in the market. So it’s very important to build one’s signature.

Everyday there are people who come and pick up 6 pieces off the rack and then replicate it at a cheaper value. I think it’s important that retailers and people should be more aware about which one is original. We see our copies and get disappointed but then we think that the industry is running on us and we should keep our game up because if we stop, there are so many people who might go out of business. We work with a lot of clusters in Bengal, Madhya Pradesh, Kutch, Andhra and Bihar. We’ve worked with Kashmir crafts earlier.

AR: What are the three things you wish you had known as a student like when you were studying?

Richard: I would say a walk into the industry before you start your own label is a must. This gives you the experience of interacting with people understanding the market. I think experiences are important, don’t do it because someone else is doing – take time to figure out what drives you or excites you. All the successful brands today are the ones that have stuck to their guns.

Yes, the market in Delhi is saturated – from Sarojini Nagar to Emporio – there are a lot of brands, everything is there and there are a lot of copies but you have to find your space in that.

It might take time like it did for us but you will eventually figure it out.

Amit: Another important thing is to constantly edit – many times, a garment would come out and we both might not like it. So it’s an immediate dump; it does not go into production or social media, it goes nowhere. That’s something that you need to be very conscious about; don’t infringe on somebody’s look or aesthetic. A lot of designers don’t really know how to edit, they are too involved with what looks good on social media.

AR: What about costing for someone who’s entering the industry?

Amit: When we started out in textiles, it cost us Rs. 90 per metre, now it costs us Rs. 250 per metre. So there is nothing that you can do and you can’t tell the weaver that ‘I want to sell, so I’m going to be paying you less’.