Line balancing presents a huge problem in most apparel manufacturing factories. Even experienced line managers the world over who have achieved some success in increasing productivity will agree that a perfect balancing does not and cannot exist.

Quite simply there are many variables and the task is then to manage them effectively. The problem is compounded by the fact that in the Apparel Industry the process is highly labour-intensive and we are dealing with human element.

However, Gescom implemented entirely new algorithms in an unusual balancing method to increase productivity. In a usual balancing method, the overall chain efficiencies is generally conditioned by the weakest operator, but with Gescom each operator can work at his maximum efficiency without being slowed down by the bundles flow to give 10 to 20% more efficiency.

For any style, times allocated to the different job stations cannot be equalized. Operators’ potential efficiencies are variable. In fact, each operator adapts his output to the variations of the flow of pieces which reaches his job station.

The key to increase line efficiency is to use the multi-skill of operators in such a way that de-bottlenecks the lines.

Invariably operators tend to slow down to fill available time when they see lesser bundles reaching their job stations.

Consequently there is no simple and permanent solution in which all operators would stay on the same job stations and would work at their individual maximum potential efficiency.

The lines’ efficiencies often average in the 50% bracket while the individual measured efficiencies of the operators ranged from 65-85 or even 90%. Average line efficiency is thus always inferior to the mean of the individual potential efficiencies of its operators.

The success therefore lies in bridging the gap between line efficiency and individual maximum potential efficiency.

Many developments in this area have been made possible through Gescom proprietary algorithm/software aimed at resolving the line balancing problem and related issues like absenteeism that impacts line efficiency.

In the traditional line balancing methods, the overall chain efficiency is generally conditioned by the weakest operator.

Gescom has inverted the paradigm. With its balancing programme (called Equival) each operator can work at his/her maximum efficiency without being slowed down by the bundles flow. The idea is to substantially reduce the invisible efficiency losses.

It is predicated upon two principles:

- Each operator must be able to work close to his maximum potential efficiency. He must never be slowed down by the flow of pieces (bundles) reaching his work station.

- In order to maintain the line efficiency at the optimum level, there must be some multi-skill operators existing who can move between 2, 3 or even 4 job stations, whenever it is necessary to maintain the bundles flow at a pre-determined level.

Obviously in order to make this happen, there are pre-requisites. One of them is the need to have a precise and full knowledge of the operators in terms of their skill sets. Each skill represents a family of processes. Within each family, a skilled operator’s potential efficiency should not vary substantially.

Operators’ Maximum Potential Efficiency

The maximum potential efficiency has to be measured for each operator. This is not difficult but a matter of detail, of observation and recording, actually a routine work for engineers in the IE department.

The procedure is like this:

1. The operator has several bundles ready.

2. Measure (through stopwatch analysis) his efficiency compared to the allocated time, adding to his cycle time the necessary personal time allocation.

3. As the operator is under observation, with enough bundles and without any disturbance, he will produce at his maximum potential efficiency.

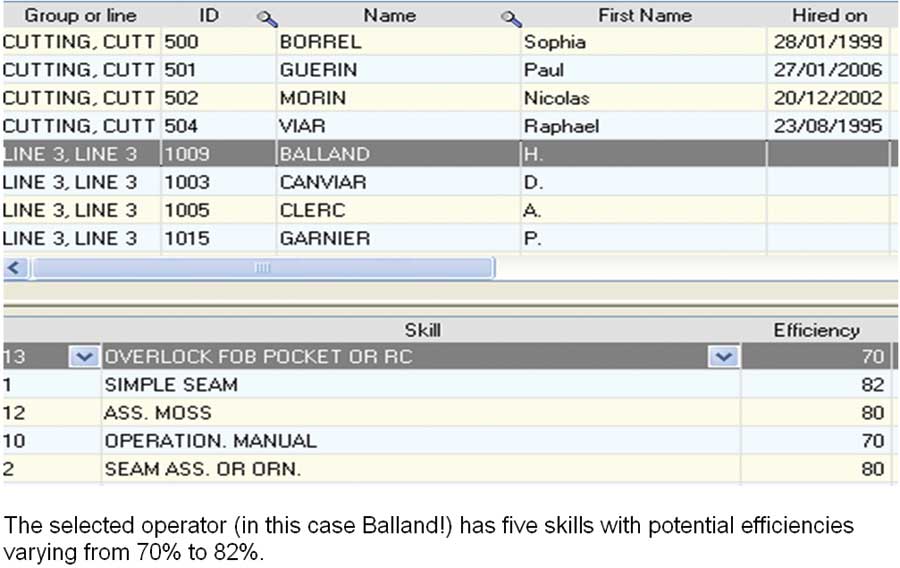

4. For the multi-skilled operators, the measurement has to be repeated for each skill. The screen shots (Table 1) shows the maximum potential efficiency for all skills that a particular operator possesses.

The selected operator (Balland) has five skills with potential efficiencies varying from 70% to 82%.

Job Station Organization

The next important step is to generate for each style/model, the list of operations that includes the necessary skills required. This means each operation is properly coded, each operation is described properly and the appropriate machine and skill is specified for that operation along with Standard Time for the operation (Table 2).

Further the operations are regrouped and included in job stations. This lets us know which operations will be done at which job station.

With the above information, how is balancing done?

Step by Step Balancing against Automatic Balancing

The basic data/information that is available is job station number and function, skill, machine code, allocated time, number of minutes (min) to be produced per day (Table 3).

For the first job station, an operator is selected from the list of all operators who has the necessary skill and then alloted to the operation. After each assignment, the number of bundles produced per day is computed. In this example, daily production target is 35 bundles. The first operator is able to produce only 13 bundles per day. Then the second operator is assigned and the procedure goes on until job station 1 has reached the target. For the last 2 stations, the daily target cannot be reached (30 bundles for station 10). Globally 150 minutes cannot be produced, when 172 min of operator’s potential production time are unused.

Obviously, this step by step process is a conventional process and cannot produce an optimum balancing.

Here the algorithm assigns operators to job stations according to their (multiple) skills in order to obtain the best possible efficiency.

Simulation

A simulation programme simulates the flow (minute by minute) and moves the operators from one job station to another job station when needed. It builds a realistic scenario

of the daily transfers and evaluates the transfer losses.

It gives practical indications to the chain managers such as: “Around 11 o’clock, Mrs X should probably move from job station 3 to job station 5. Watch the ‘in process’ quantity of pieces between job station 4 and job station 5. As soon as it is below 2 bundles, move Mrs X to job station 5.”

Practical Utilization

As soon as new styles/prototypes are available (including list of operations and allocated times), they can be simulated by the algorithm for all lines that are technically able to produce these styles. Depending on the breakdown of operator skills and efficiencies in the various chains, the results can be highly variable.

It can throw up numerous workable data such as:

- To the machines department: Future needs by types of machines for the coming season.

- To the planning department: The line in which a style should preferably be launched.

- To the training department: The list of skills that should be developed in each line to sustain the best possible efficiency.

On a daily basis, the balancing is modified according to the absenteeism and previous day’s in process quantities of pieces between job stations.