Sewing involves complex tasks of manipulating the fabric, the material and its orientation through an industrial sewing machine. The sewing process may involve one or more than one ply. Sewing decorative patterns or attaching patches, appliqués requires movement of fabrics in x-y coordinate in respect to needle point. The pattern tacking (earlier called x-y tacker) cyclic sewing machine, which has clamp feed for fabric movement, is an example of the same. Joining more than one ply along fabric edges requires continuous sewing machine, where the direction of feeding of fabric is straight and away from the sewing operator. It is the operator who manipulates the fabric direction to sew curve and other shapes of material. Over the time, the process of guiding of material during sewing has evolved; from cam follower to mechatronics technology to be precise. And now the recent developments in vision sewing technology have opened up a new frontier in automated sewing. Dr. Prabir Jana, NIFT Delhi and Rick Frye, Director of Engineering, Brother International write…

What is Vision Sewing?

When we think of the term ‘vision sewing’, we assume it involves some type of sewing machine with a camera and rightly so, but what is not understood is how the two work together. While there is no clear technical definition in the sewn products industry for ‘vision sewing’ we can say that vision sewing often involves an industrial camera and a processor with software that is integrated with the machine controller of the industrial sewing machine to perform ‘complex tasks’. When we talk about vision sewing, we are talking about either conventional single needle lockstitch or chainstitch machines integrated with vision systems or an electronically programmable pattern sewing machine integrated with vision systems.

Sewing speed of up to 2,800 stitches per minute can be achieved by Brother Vision Sewing System.

Brother Vision Sewing System

An electronic programmable sewing machine is equipped with a work holder to hold the work-piece which it moves around in a pre-programmed sewing path or pattern. Such a setup requires a processor to control the operation and stepper or servo motors to control the movement to create the desired sewing patterns.

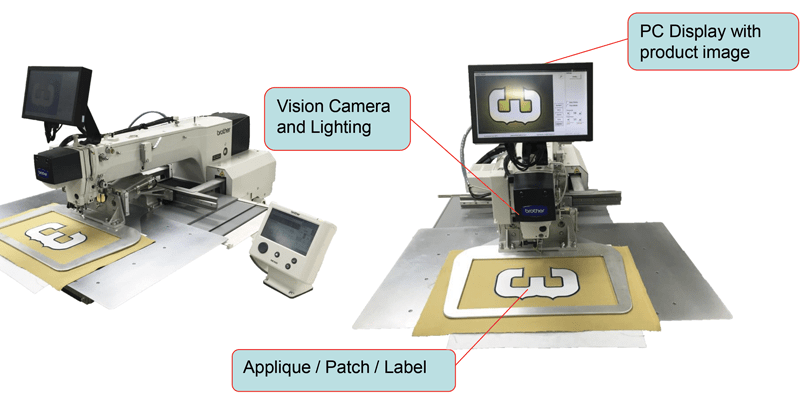

Brother vision sewing system is furthering de-skilling of the pattern sewing machine. It is a programmable sewing machine that employs an industrial personal computer (PC) with software, custom camera, and lighting, to automatically create a stitch pattern around the perimeter of a regular or irregular shaped object (patch, label, appliqué, etc.) within the sewing area of the machine. These systems can cover areas from 220mm x 100m to 300mm x 200mm. The vision sewing system is specifically designed for use to attach items such as labels, patches, appliqués of any shape to various fabrics or garments. Since customization is growing, it can prove to be a big market for vision sewing machines.

Vetron AutoSeam can track the movement of fabric with intelligent cameras and also control it under the needle on a stitch-by-stitch basis.

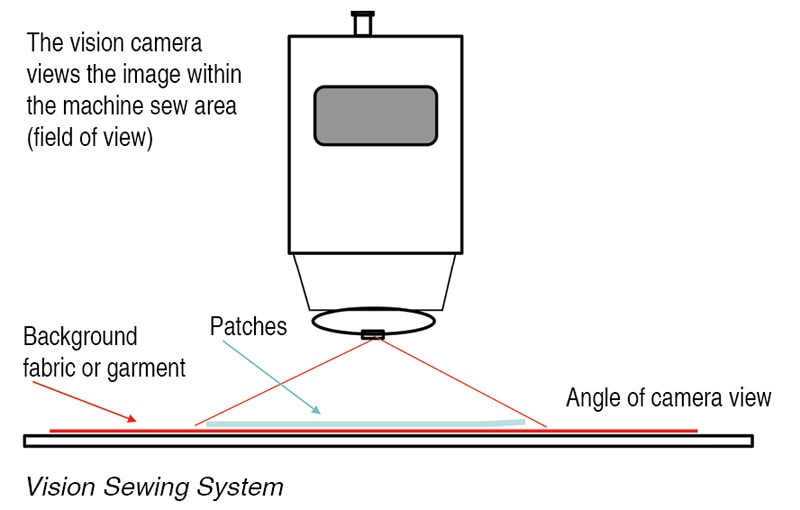

The vision sewing system creates the required sewing pattern of the image within the machine sewing area by comparing the colour of the image border to the colour of the background fabric or garment. This process of generating the patch image, creating the sewing pattern, and transferring it to the electronic programmable sewing machine typically requires three seconds or less, depending on the quantity of stitches of the sewing pattern programme generated. Sewing speed of up to 2,800 stitches per minute can be achieved in such a system, although it is dependent on the product being sewn (material) and the thread being used. The type of work clamps used for the machine is dependent on the application. There are various stitch types available with the machine such as straight or zig-zag which can easily be selected. In straight stitch option, the stitch length can be selected on 0.1 mm increments, whereas in zig-zag stitch, the user can choose either a ‘V’ or ‘N’ type stitch that allows a stitch width of up to 12mm. The machine even allows the user to choose a starting point of the pattern within 8 different locations around the perimeter of the patch or shape.

A sewing pattern is created each time an item is presented to the machine for sewing, making it easier to attach regular- or irregular-shaped patches or labels. The largest size patch, letter, or appliqué that can be sewn is limited only by the sewing area (300mm x 200mm) of the machine. Whereas the smallest size patch, letter, or an appliqué that can be detected and sewn is within the area of 50mm. The vision sewing system is capable of sewing multiple patches such as letters or numbers in one operation as long as they fit within the machine sew area.

To hold the patch to the garment while it is being sewn, either the patch is applied with adhesive at its back or many patch’s, applique’s, letters, numbers, can be purchased with an adhesive backing already applied, while other methods for adhesives/applicators include tapes, dots, and spray adhesives.

Watch the working live at (https://www.brother-usa.com/IndPrintSewEmb/VisionSewing)

The key benefits of vision system include a consistent sewing speed for multiple patch sewing, automatic sewing of multi-layered letters/numbers, improved/less handling of the garment or fabric. In addition to this, handling the machine requires no operator sewing skills, while a single operator can operate multiple machines at any point of time.

ThreadVision System from SoftWear Automation

ThreadVision is a patented, high-speed vision system specifically designed for fabrics. The system tracks individual threads in each fabric, redefining the traditional coordinate system to thread-count, allowing for high accuracy panel tracking regardless of deformation. Automatic sewing machine from SoftWear Automation combines a patented ThreadVision System with multi-degree freedom feed dogs to fully automate the sewing process. By controlling the feed and orientation of the fabric using advanced dogs, the automatic sewing machine ensures both reliability and repeatability removing piece-to-piece variations from the garment manufacturing industry while at the same time reducing operation costs for the manufacturer.

Watch the working live at (https://www.youtube.com/watch?v=Uk3kNnHZdl0)

Vetron AutoSeam

China-based sewing machine manufacturer VETRON, a European division of Typical International Corporation, has developed another form of vision sewing where two plies of material are placed at any conventional lockstitch or chainstitch machine and it is guided through the sewing machine (by the vision system) on an intelligent, stitch-by-stitch basis while the two materials are sewn together.

Vetron AutoSeam – an automated sewing machine – upgraded from the company’s standard sewing machine. It is capable of automated sewing as it can track the movement of fabric with intelligent cameras and control the movement of the fabric under the needle on a stitch-by-stitch basis. AutoSeam identifies, adjusts and sews together the edges of the material layers stitch-by-stitch. The machine is focused on processing middle to heavy materials used mainly in the automotive, leather or furniture industry.

Watch the working live at (https://www.youtube.com/watch?v=1GUhlfjqQmQ)

The image processing system for the VETRON AutoSeam is designed to be a cost-effective solution capable of finding the material edge position, guide the mechanical parts to move the material under the needle and track the position of the material to ensure the precise sewing at every step.

Image processing systems require enhanced illumination of the work piece for image capture. High inspection speeds typically require sensitive camera and powerful lenses. In many cases, the easier option is to modify or improve the lighting situation to boost the image brightness. There are a variety of options for attaining greater image brightness: increasing the ambient light and sculpting the light using lenses or flashes to create a suitable light source are two examples.

The common feature between Vetron AutoSeam and ThreadVision System is additional lighting for Vision System. While the ThreadVision System uses red colour diffused lighting, the AutoSeam uses green colour flashlight.

But it’s not just the lighting strength that’s important. The path that the light moves through the lens to the camera matters too. During image processing, the reflections off the smooth surfaces may actually be desired to deliver high light intensities on straight, low-reflecting surfaces. For objects with many surfaces reflecting in various direction, diffuse light is better. The massive computation required by AutoSeam high speed vision system is provided with an embedded system control box that processes and controls the position and movement of the material and also machine operations. The specialized software for AutoSeam controls everything in the operation from capturing the images, processing the images, to controlling the movement and tracking the material.

Operational area to the future…

While the Brother Vision Sewing System is for cyclic operation, both ThreadVision and AutoSeam address the continuous sewing operation. AutoSeam demonstration video shows that a convex and another concave edge can be joined together without any human interference. Currently the Brother Vision Sewing System can work only with contrasting colour of patches and sews complete outline of patches. An upgrade of image processing and tweaking of software program in near future can possibly work with similar colour patches and sewing of selective edges of the patches.